Transcyko Drop-In Replacement of SEW Eurodrive Gearboxes

The comprehensive catalog of Transcyko gearboxes, motors and servo motors guarantees we can supply alternatives to other major gearbox manufacturers’ products. Transcyko TR, TK, TS and TF series gearboxes can be fitted as drop-in replacements for SEW Eurodrive gearboxes for high performance, efficiency, and easy maintenance in a cost-effective package.

What are the features of Transcyko TR, TK, TS & TF series gearboxes & gearmotors?

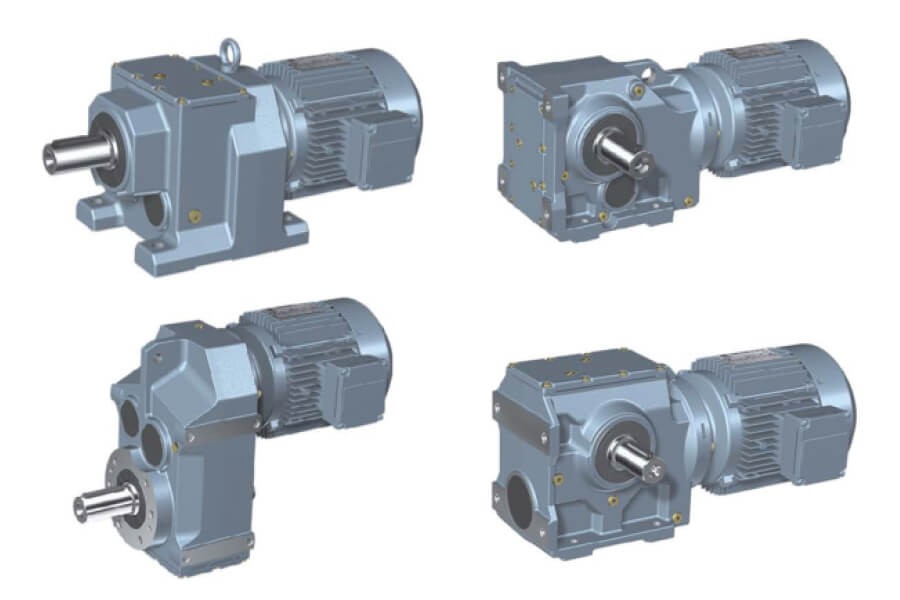

The Transcyko TR, TK, TS, and TF series are a new generation of mechanical-electrical integrated parallel shaft helical gearmotors. The modular design of our gearboxes and gearmotors allows the use of any type of motor drive for maximum flexibility. This makes these Transcyko products able to match or exceed the performance and operational requirements of any competing products in this class.

What types of motors are compatible with Transcyko modular gearboxes?

- standard motors

- brake motors

- explosion-proof motors

- frequency conversion motors

- servo motors

- IEC motors

Transcyko modular gearmotors can be mounted in six orientations. When added to the flexibility of motor options, this makes the TR, TK, TS and TF series gearmotors a widely adopted choice for many industrial applications. The range of possible housings and configurations has led to our TR, TK, TS and TF series being adopted for clean manufacturing, food processing, transport, mining and hazardous industrial applications.

What are 6 typical applications of Transcyko TR, TK, TS and TF series gearmotors?

- Textile & clothing manufacturing

- Food & beverage

- Chemical Industries

- Industrial Automation

- Logistics & Warehousing

- Mining & Metallurgy

- Waste & Environmental management

Why are Transcyko Gearmotors the Best Alternative for SEW Eurodrive Gearboxes?

The flexibility and performance characteristics of Transcyko TR, TF, TK and TS series gearmotors enables an easy direct match to SEW eurodrive gearbox installations for simple drop-in replacement without difficulty. Transmission ratios are easily customized to any equivalent SEW Eurodrive product, and compact footprints do not require modifications to existing installations.

- Fine stage transmission ratios cover a wide range of performance requirements

- Compact designs to fit in available space

- Low noise & vibration characteristics

- Reliable, reduced wear, low maintenance designs

- Modular designs can be combined to meet any transmission requirements

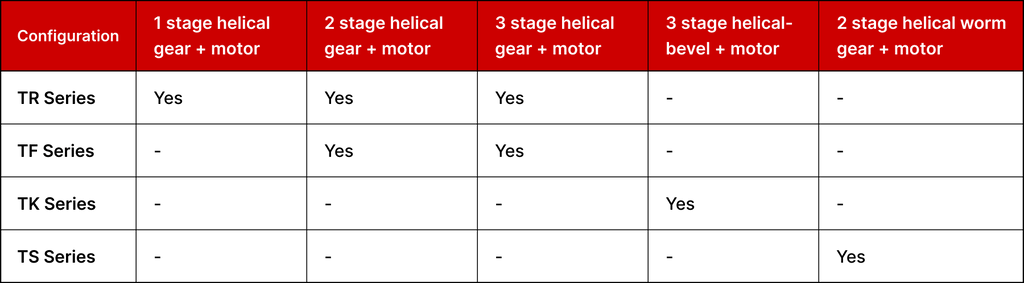

TR Series gearmotors have 1, 2 or 3-stage helical gear units and a motor. The TF series features 2 or 3-stage helical gear units and motor, and the TK series has a 3 stage helical-bevel gearbox with motor. TS series gearmotors combine a 2-stage helical worm gear unit with a motor. There is a TR, TF, TK or TS series gearmotor to suit every industrial application.

Transcyko gearmotors are ruggedly built to high quality standards.

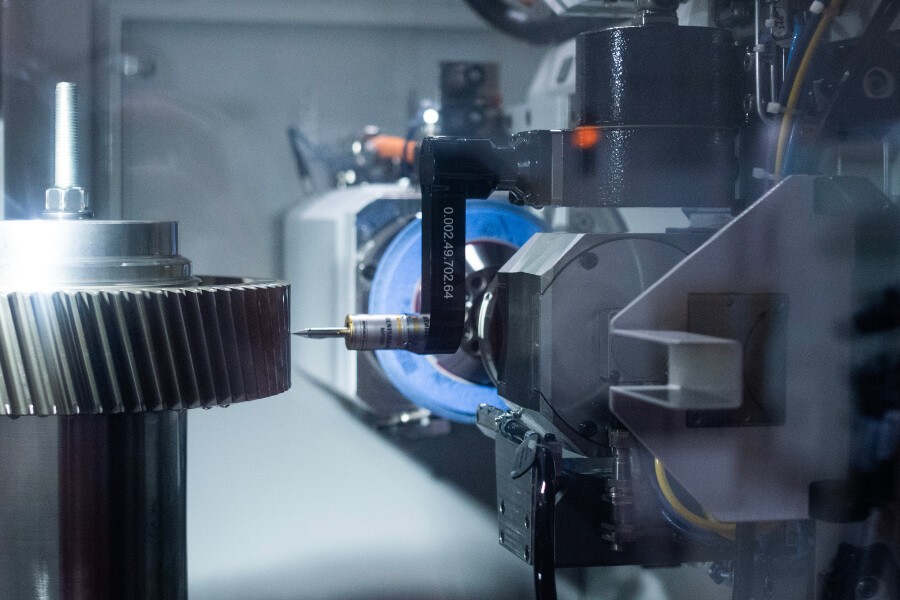

Helical gears and worm drives are manufactured from surface hardened steel alloys, with high precision bronze worm wheels, and housed in rugged cast iron casings. The combination of high quality internal components and durable housings delivers high performance and reliability with long service life in a reduced volume, light, quiet, highly efficient package.

- High quality, low maintenance construction materials

- Easy drop in to replace standard installation formats

- Excellent after-sales support & service

Our quality management systems are thorough and utilize high precision manual and automated inspection techniques and technology to ensure fault-free manufacturing. We pride ourselves on our very high quality standards and excellent customer partnerships.

Flexible gearmotor design for any application

We manufacture more than ten different models of TR, TF, TK and TS parallel shaft helical gearmotors. These can be combined with our TRF series to achieve significant multi-stage gear reduction.

- Power: 0.12-200 kW

- Ratio: 1.3-33818

- Torque: 69-50000 Nm

All models can be supplied with a range of foot or flange mountings to suit customer requirements for any installation format, and come with excellent after sales gearbox & gearmotor servicing from our global network.

Gearboxes with quality & reliability you can trust, from Transcyko

Transcyko offers a complete package of high quality, thoroughly tested products with excellent, rapid after sales service and customer support. The long service life and low maintenance costs of Transcyko gearboxes and gearmotors reduces the total lifetime costs compared to our competitors, without compromising on quality and reliability.

- High reliability

- Long service life

- Low service & maintenance costs

- Energy efficiency

- Excellent after sales support

- One-stop gearbox supplier

We know it can be difficult to identify the best alternatives to your current gearbox supplier, with so many low quality gearboxes on the market, including fakes using false marketing. We have encountered this ourselves, with companies attempting to copy our designs, so we are very responsive to your concerns.

Taiwanese gearbox manufacturing excellence

Genuine Transcyko gearboxes are made in Taiwan to the highest international quality standards, using the best materials from our well established Tier 1 supply chain. All products are tested with 3D CMM, automatic and manual quality checks. Our engineers are on-hand to answer any questions about compatibility, and discuss exact specifications and performance characteristics.

Which gearboxes have exact Transcyko equivalents?

We supply drop-in solutions for many different products and applications. As well as gearboxes that are excellent alternatives to SEW Eurodrive products, we manufacture direct replacements for Sumitomo cyclo, Bonfiglioli planetary, and Zambello injection molding gearboxes, speed reducers and gear motors.

- precision cycloidal gearboxes

- robotic speed reducers

- cyclo drives for servo motors

- helical bevel gearboxes

Contact us to discuss how we can supply new gearboxes and gear motors or gearbox upgrades for your existing machinery. We have extensive experience in manufacturing gearboxes and speed reducers to meet a very wide range of engineering requirements to the highest quality standards for optimum performance and reliability.