Precision CNC Manufacturing

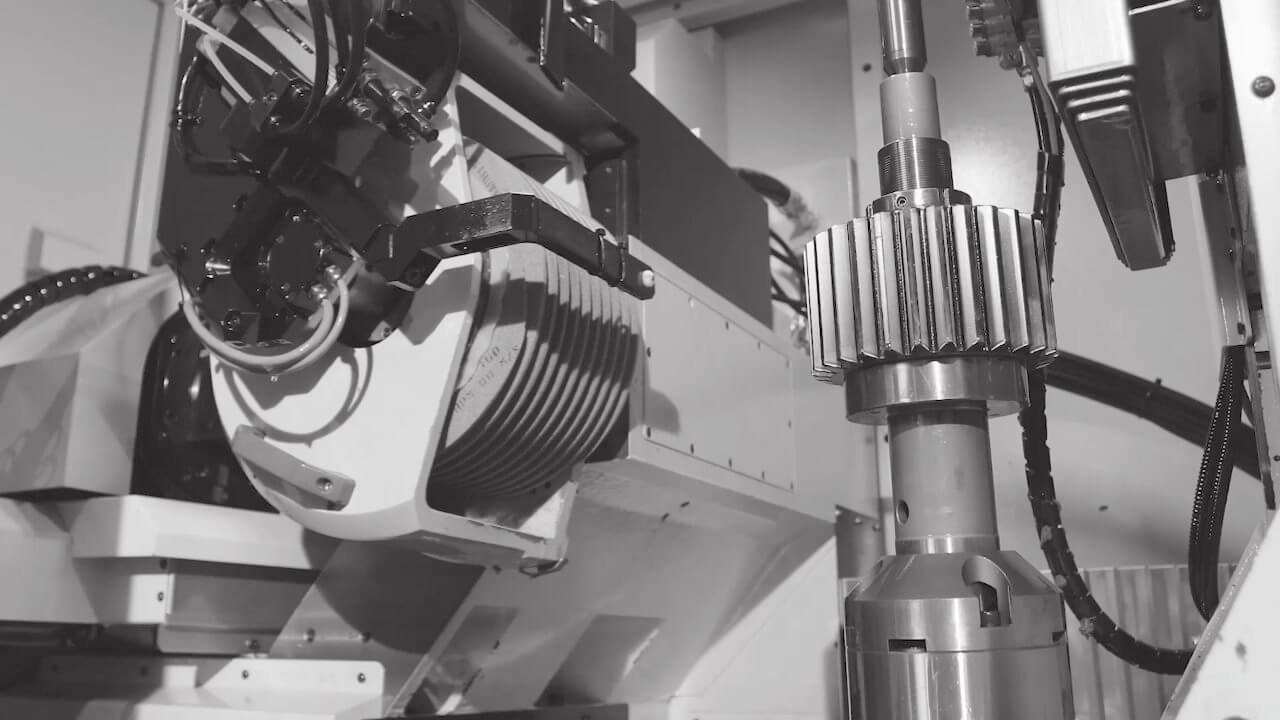

We understand that gear reducer production requires extreme precision working within exacting tolerances for each and every speed reducer produced.

We have invested in some of the most advanced machining technologies from Germany and Japan to allow us to guarantee the precision and stable quality of every product we make.

We perform all reducer machining operations in house from rough machining to fine finishing, gear grinding and hobbing and all aspects of quality control and assembly too.

Over the decades we have amassed a wealth of expertise in reducer machining and production, from lightweight to heavy-duty speed reducers. Our experienced technicians and machinists are fully trained and regularly receive additional update training as new technologies and requirements appear.

Gear Reducer Quality

Quality control is an important aspect of the production of our gear reducers and speed reducers. Our quality department completes a range of measurements on each unit to ensure that tolerances and machining quality are maintained.Standard Measurements Include:

- 3D Coordinate Measurement

- Surface Roughness

- Material Hardness

- Gear Profile Measurement