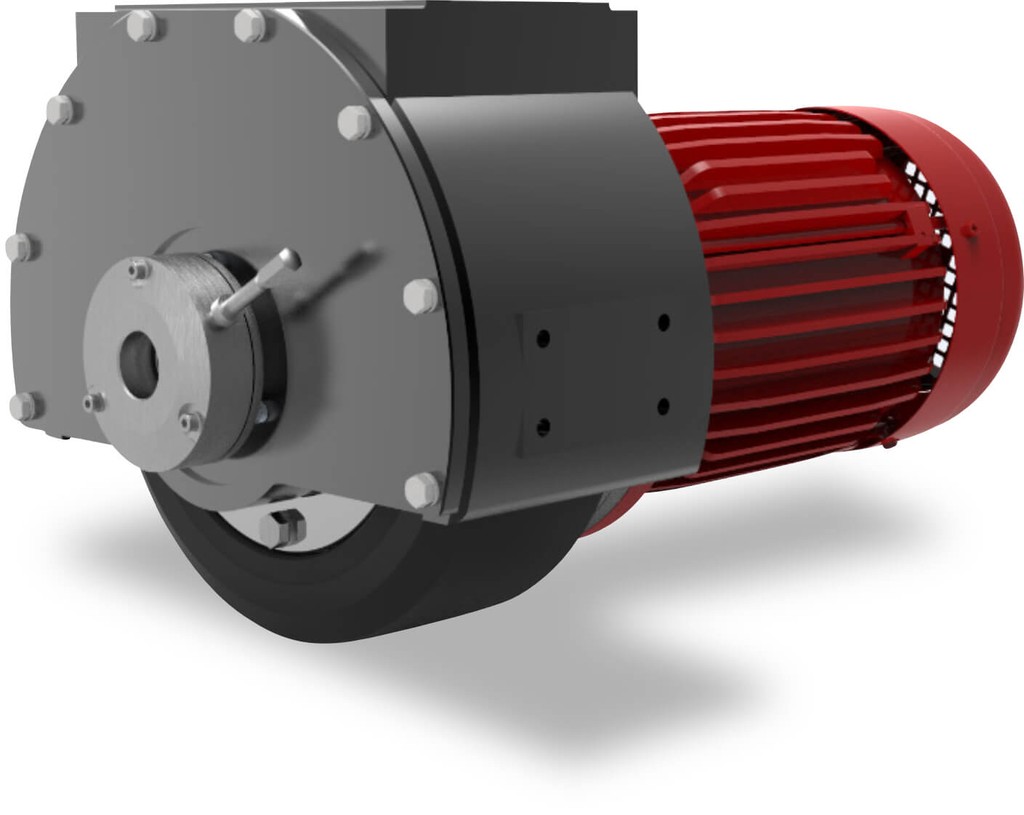

Cyclo Centrifuge Drives

Cycloidal Derivatives-TZS

Cyclo Drive Key Features

- Circular Design

- High Reduction Ratio 6:1 To 87:1 In One Stage

- High Shock Overload

- 30,000-40,000 Nm Maximum Output Torque

- Customized Design For Centrifugal Applications And For Higher Output Torque More Than 40,000 Nm

Cyclo Drive Applications

- Centrifuges With A Screw Conveyor For Conveying Solids

- Oil /solids separation (oil well drilling, refining, de-watering)

- Pharmaceutical

- Industrial and biological wastewater treatment

- Precious metals Recovery

- Food processing (olive oil, wine, fruit juice)

- Chemical

Speed Reducers for Rail Guided Vehicles (RGV)

Cycloidal Derivatives-TCS

Travel Motor Key Features

- Compact: ½ Of Conventional Helical Gear Drive

- Light Weight: ⅓ Of Conventional

- Helical Gear Drive

- Easy To Apply In Limited Space

- Low Noise

- High Efficiency to 95%

- Long Life

- High Shock Resistance

Travel Motor Applications

- Automated warehouse/logistic in heavy industries

- AGV

Parallel and Right Angle Output Buddybox

Cycloidal Derivatives-TBX Series

Cyclo Drive Key Features

| Ratios | 17.5:1 to 304:1 and greater |

| Torque | Up to 6840 Nm |

| HP | 1/8 to 40 HP |

| Mounting | Hollow Shaft, Flange, Face |

| Options | Integral Motor, C-Face |

| Structure | Combines cycloidal reducer and a single stage offset parallel helical gearbox or bevel right angle shaft in a rugged integral, shaft-mounted design |

Cyclo Drive Applications

- Centrifuges With A Screw Conveyor

For Conveying Solids - material handling

- rolling mill table

- conveyor

- screw conveyor

- sortation system

- shredders

- rotating biological contactor

- belt filter press

- mixer/blender

- food processing

- wire drawing machines

Speed Reducer Manufacturer

High Precision & Quality Controlled Production

Transcyko is the number one brand in Taiwan and we have manufactured speed reducers and gearboxes for over 30 years through our brand. We have a close partnership with the Industrial Technology Research Institute to work on the manufacturing and testing processes for our cyclo drives and other products.

This testing and research looks at a range of areas including the following: Rated Frequency, Lost Motion, Backlash, and many others.

The results of this research allowed us to optimise

Best Speed Reducer Support & Service

Keeping your production running and providing you with excellent support is important to us. The design of our speed reducers includes standard size components that can be dimensionally replaced with standard components for other sources if needed. In addition, we keep a large stock of all standard components on hand to ensure we can provide rapid ship support whenever you may need it.