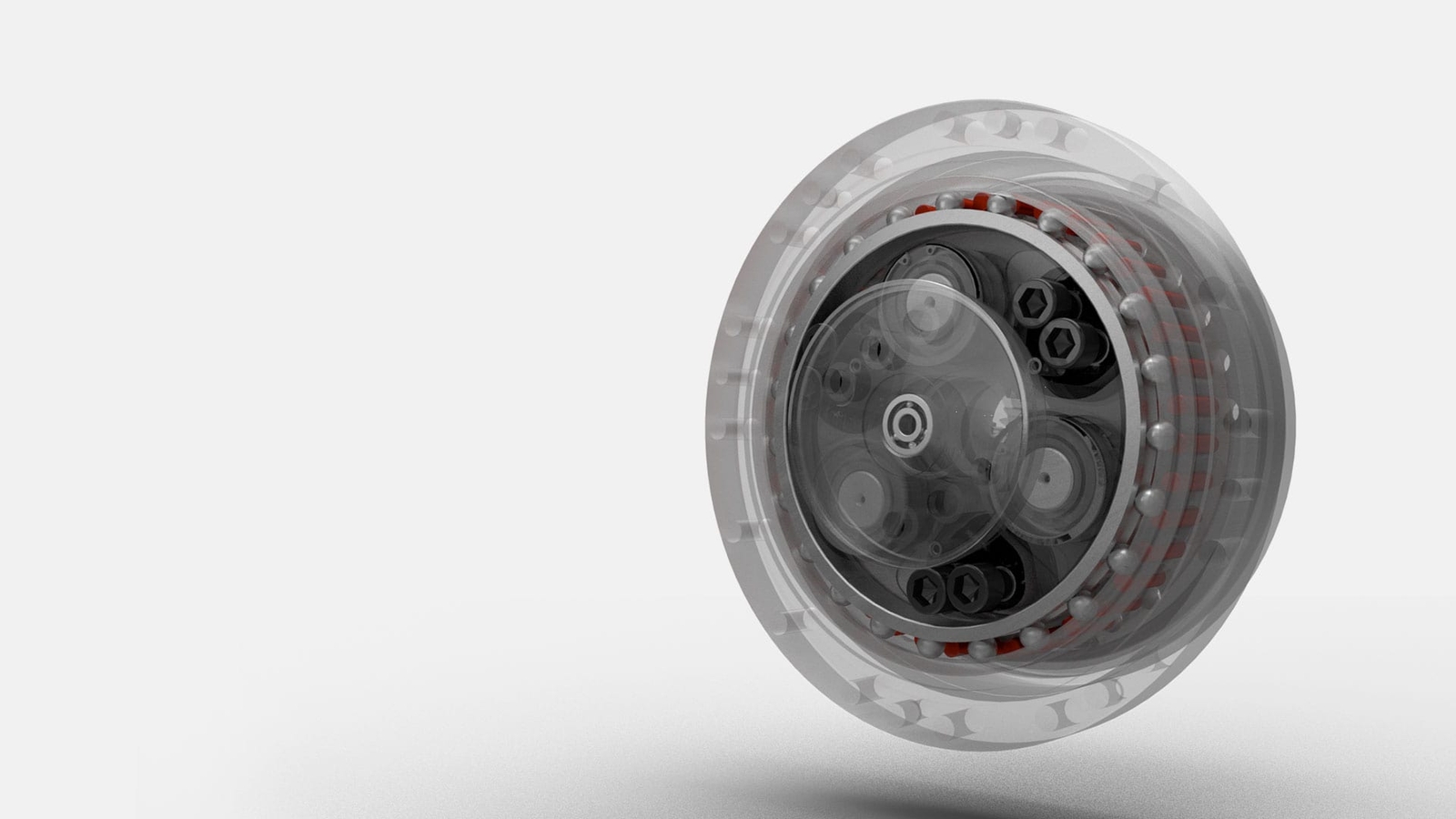

Reducer Precision

Speed Reducer & Gearbox Quality

Robotic Reducer Key Features

- Large Simultaneously Engaged Gear Teeth

- Compact – Light Weight

- Rigid Construction – Heavy Loading

- Minimal Backlash (As Low As Max 1 Arc/Min)

- Smooth Motion

- Accurate Positioning

- Main Bearing Built-In Type (E Type)

- Hollow Shaft Type (C Type)

Robotic Reducer Sales Point

- Dimensional Replaceable With Existing Brands Including Internal Parts

- Economically Benefit To Customers In Terms Of Maintenance, Repair Or Stock Purpose

- Customized Gearbox Available

- High Torsional Rigidity & Low Backlash For Smooth Running

- Short Lead Time

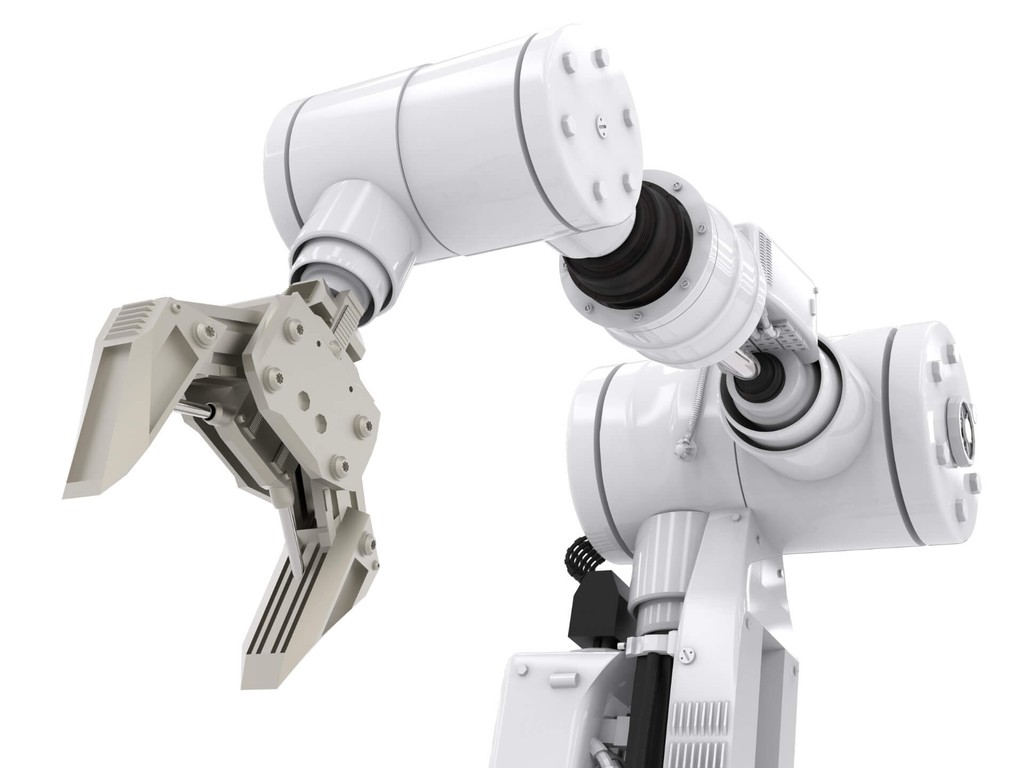

Machine Tools

Industrial Equipment Where Precision Positioning

Factory Robots

Dedicated to Helical Gearbox Excellence

Partnership With Industrial Technology Research Institute

In the plastics injection molding and Rubber production industries, production machinery is the heart of your business and keeping it well supported an operation is vital. In the design of our helical gearboxes and Helical Bevel gearboxes for injection molding machines and other plastics industry applications we have ensured that we use standardized components so that they can always be replaced with generics should the need arise.

We also have a large onsite stock of replacement parts for our helical gearboxes and helical bevel gearboxes which can be shipped out whenever the need arises.

Support and Service

We understand how important rapid efficient service is for your business. We maintain an extensive stock of parts for all our reducers and can provide rapid on site service if you should need it. Our components are also standard sizes and can be dimensionally replaced with standard parts from other brands including internal components.