Transcyko ZS Cyclo Drives for Centrifuges

Compact, high torque, durable, cost-effective and highly reliable. Transcyko ZS Cyclo Drives for centrifuges are directly interchangeable with the products of other leading manufacturers.

Transcyko ZS Cyclo Brand Interchangeability

We work with global brands to ensure that our drives are compatible with the same equipment for the same applications. A feature of our cyclo drives and maintenance service is our ability to provide alternative drives that will work seamlessly with existing customer equipmeht

Advantages of Our Cyclo Drives

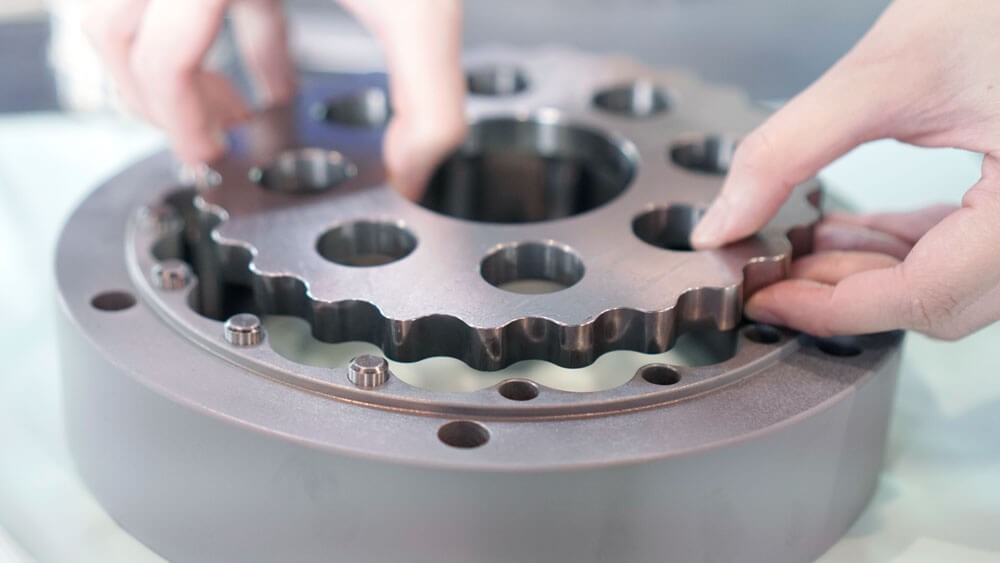

Cyclo drives use epicyclic cycloidal gearing, which means the gears rotate around each other inside the casing instead of being positioned inline. This enables very compact, short designs that are ideal for centrifuges. Unlike inline gearboxes, cyclo gears operate constantly in compression and not in shear.

The compact balanced design is inherently stable, has few moving parts, which increases strength and reliability and reduces noise and vibration. We bring our long experience as a Taiwan speed reducer manufacturer to our cyclo drive designs. There are several features of Transcyko cyclo ZS drives that make them the best choice for heavy duty applications that require high reliability:

- Shared Load For High Shock Resistance

- High Output Torque

- Large Single-Stage Reduction Ratios

- High Reliability And Predictable Service Cycles

Shared Load For High Shock Resistance

As well as operating in compression, the epicyclic cyclo design shares the load across multiple gears. Transcyko ZS cyclo drives can withstand shock loadings many times higher than the shock loads that would damage a traditional gearbox. This is because more teeth are engaged in cyclo designs at any time than in a traditional gear design

The concentrated shear forces of inline gearboxes cause failure of gear teeth and drive shafts because they have small areas in contact when the drive shaft is rotating. ZS cyclo drives reduce risk of failure by design. They are extremely durable and reliable because forces are shared evenly between components in a balanced system

High Output Torque Cyclo Drives

Sharing the load across multiple gears simultaneously and operating in compression reduces wear on the gearbox as well as making it very robust and reliable. The strength and shock resistance of ZS cyclo drives enables very high torque operation.

Our ZS series cyclo drives can sustain output torques in a range of 30-40,000Nm as standard. As a vertically integrated Taiwn speed reducer manufacturer we control all stages of the design process. This means our in-house design team can build drives with higher torque capabilities to meet any customer requirement.

Large Single Stage Reduction Ratios

High torque operation and shock resistance enables large single-stage changes in speed that would damage a standard gearbox. This enables ZS cyclo drives to offer very high performance, while being very reliable and long-lasting even in the most demanding applications.

Our Cycloidal Derivative ZS cyclo drives are designed to achieve single stage reduction ratios from 6:1 to 87:1. This makes them suitable for both low speed and very high speed applications in a single step without the need for additional stages.

High Reliability And Predictable Service Cycles

In business critical operations cyclo drives are the most reliable and durable speed reducers available. The high overload reserves and easy roll-off movement of the gears reduces internal pressure, increases thermal safety, and almost eliminates wear even at very slow speeds.

Because cyclo drives share loads evenly between components this reduces the risk of unexpected failures and stoppages. Service intervals can be planned to meet the demands of the business cycle without costly interruptions.

ZS Cyclo Drive Applications

Cyclo drives are very versatile and can be employed cost-effectively in many speed reducing applications. This is primarily because of their high speed, high torque capabilities and the wide range of ratios that they offer, but they also have other excellent features.

Because cyclo ZS drives are compact and self-contained they can easily be built as sealed units, and the reduced vibration and noise makes them quieter and less likely to leak than other types of drive. This makes cyclo ZS drives the best choice for food-grade, chemical and pharmaceutical businesses where lubricant contamination and leaks are completely unacceptable.

Globally our customers employ Transcyko ZS drives in a wide range of operations and applications:

- Speed Reducers For Decanter Separators

- Chemical Refining and Separation

- Centrifuges With A Screw Conveyor For Conveying Solids

- Oil / Solids Separation

- Pharmaceutical Refining and Manufacturing

- Industrial and Biological Wastewater Treatment

- Precious Metals Recovery

- Food Processing

The range of possibilities is not limited to these examples. Our technical and design teams are happy to discuss any requirements and offer advice and suggestions based on our long and successful experience in drive design, operation and maintenance.

Transcyko Cyclo ZS Drives: The Perfect Solution

Transcyko ZS drives are the perfect solution for high performance speed reduction applications. We focus on offering high quality, performance and excellent maintenance and service support for our customers. Our ZS cyclo drives offer:

- High Quality With High Performance

- Excellent Maintenance and Service Support

- Cross-Compatible with Other Leading Brands

High Quality With High Performance

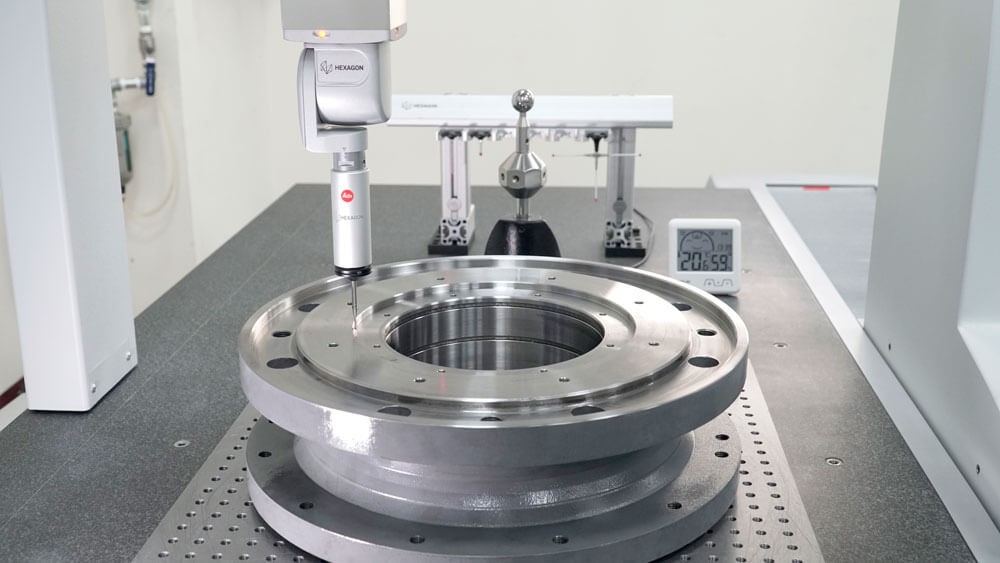

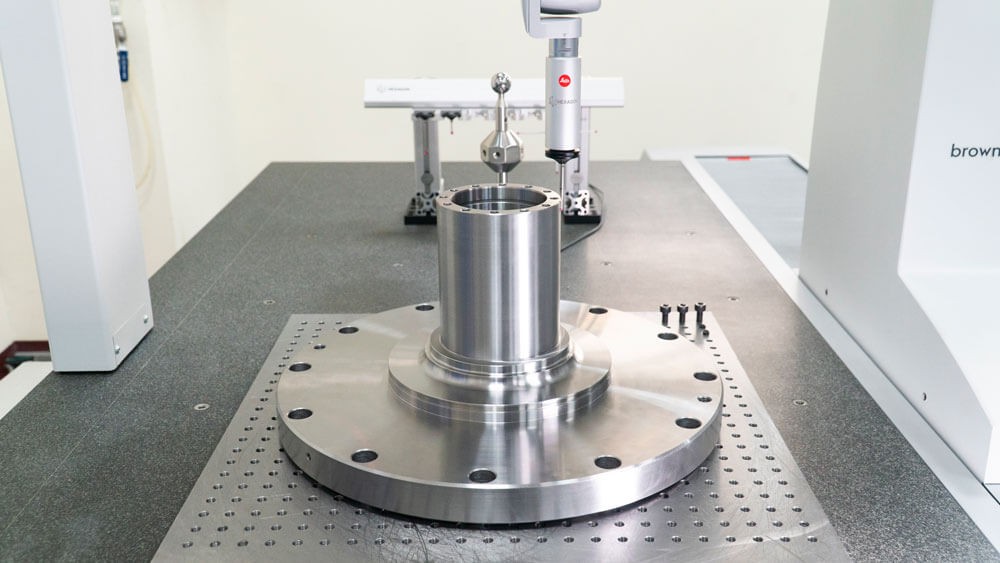

Transcyko carries out stringent quality control testing and measurement on all components to ensure our ZS cyclo drives are perfectly balanced and ready to provide reliable low maintenance, high performance and cost-effective solutions for our customers.

Excellent Maintenance and Service Support

At Transcyko we maintain a responsive service team to ensure that your cyclo drives continue to operate smoothly and reliably no matter how harsh or demanding the environment. Our in-house expert service team offers 24/7 support to our customers regardless of the size or complexity of your business needs.

Cross-Compatible with Other Leading Brands

Transcyko ZS drives are offered in a form factor that enables them to be used as seamless replacements for other leading brands. We also manufacture components that are direct replacements for cyclo drives offered by other manufacturers to keep your business running smoothly.

Transcyko: The Logical Choice

We offer our customers a one-stop shop for your cyclo drive requirements, no matter how large or how small. Our in-house design and service teams offer rapid and effective global support for all your servicing and maintenance needs.

We are always happy to offer technical advice and assistance at all stages of your business process to ensure you get the best possible drive for your requirements at a cost-effective price. Our customers have discovered that Transcyko cyclo drives are the logical choice and we are the ideal partner to help them achieve and maintain business success.