Transcyko Drop In Replacement of Zambello Injection Molding & Rubber Extruder Gearboxes

Transcyko helical bevel TEX series single screw extruder gearboxes and TIN series injection molding gearboxes offer a high quality, competitively priced, drop-in replacement for Zambello single screw extruder and injection molding gearboxes.

What are the ideal capabilities and characteristics of injection molding & rubber extrusion gearboxes?

Modern injection molding requires screw extruders that build high pressures at high speed to minimize cycle times. This maximizes throughput efficiency and accelerates production output. To manage the high stresses on machinery, gearbox reliability and extended service life are critically important when choosing injection molding and rubber extrusion gearboxes.

- Rapid injection molding cycle times

- Extended service life

- High reliability & low maintenance costs

Extrusion lines in the automotive, packaging, home appliance, food and beverage, electronics, entertainment and medical sectors depend upon reliable helical bevel gearboxes to achieve consistent results. This is why the best injection molding and rubber extrusion gearboxes are constructed of high quality materials, and engineered to deliver smooth, consistent operation.

How do Transcyko gearboxes meet the requirements of the injection molding & rubber extrusion industries?

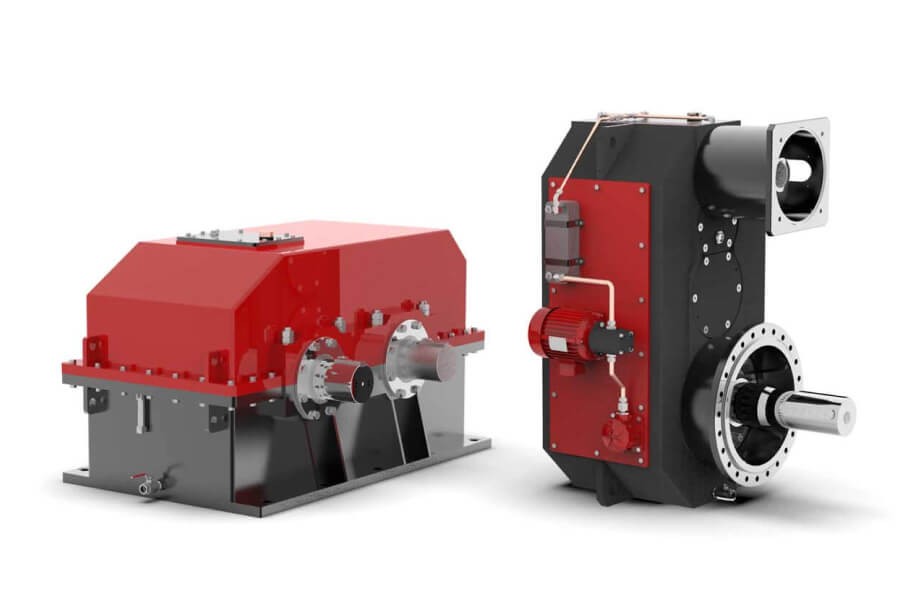

Transcyko TIN series gearboxes have been specially designed to power the screw drive of the plasticizing cylinder in injection molding machines. The Transcyko helical bevel gearbox transmits increased torque and accepts high input revolutions without increasing noise, while maintaining a service ratio that exceeds 95%.

- Easy drop-in replacement for standard designs

- High quality construction materials

- Options for injection molding & extrusion

- Excellent after-sales service & support

Standardized helical gearbox designs for easy drop-in replacement

U-shaped design configuration optimizes the system of motor, gearbox, drive-screw and plastifying cylinder to easily mate with standard injection molding machinery, enabling easy upgrades by drop-in replacement of existing gearboxes with a Transcyko equivalent.

Gearbox options for any injection molding or rubber extrusion requirements

Our long experience of meeting the specific requirements of our customers across a wide range of industries and applications enables us to offer many different options from our extensive catalog of standard designs and variants. We are confident that no matter what your engineering specification, we can supply you with a matching gearbox solution.

Excellent global after-sales and maintenance support from Transycko

With rapid global after-sales and maintenance support, Transcyko helical gearboxes are an attractive alternative when you are looking to upgrade or renew your existing injection molding or rubber extrusion lines.

Helical gearbox manufacturing to outstanding quality levels

Transcyko quality control uses 3D CMM, manual and automated inspection to guarantee quality. Our long established partnerships with Tier 1 stock suppliers gives us access to the highest quality steels and component materials, enabling us to maintain very consistent quality standards across our entire range of gearboxes and speed reducers.

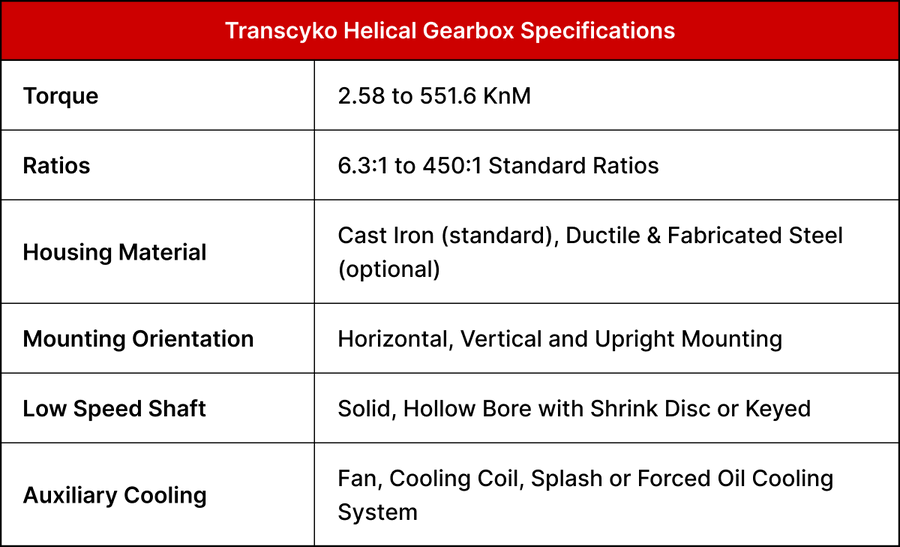

Cases are made of gray cast iron FC250, ductile cast iron FCD450 or welded steel depending on customer requirements. Gears are made of case-hardened steel 18CrNiMo7-6, with the helical teeth ground to DIN6 quality standards to reduce noise, increase efficiency and extend working life.

What are the realistic alternatives to Zambello extruder & injection molding gearboxes?

It can be difficult to make the decision to switch from a well known manufacturer of specialized gearboxes, especially when there are manufacturers producing low quality replica gearboxes from substandard materials. This is a problem we have encountered ourselves, with companies attempting to copy our designs and passing off inferior replicas as Transcyko products.

With a genuine Transcyko gearbox, however, you can rest assured that our Taiwanese made gearboxes are built to international standards and offer the same or better performance as other major manufacturers. Our team of experienced engineers and sales representatives are available to answer any questions you may have, and to verify compatibility and quality.

What about maintenance & servicing costs?

If you feel you are locked in to a single manufacturer of helical gearboxes with high maintenance, spare parts and support costs you may be surprised to discover how cost effective a Transcyko alternative can be.

Our maintenance services are competitively priced, and the lifetime costs of Transcyko gearboxes are low because our gearboxes are manufactured to very high standards, with excellent production management and quality control systems. This increases service reliability and keeps costs down.

Which Zambello products can be replaced by Transcyko equivalents?

We are able to supply drop-in solutions for almost every injection molding or extrusion gearbox in the Zambello product range. Contact us to discover the Transcyko answer to any specific gearbox and machinery configuration you are interested in upgrading or replacing.