Precision Gearboxes for Semiconductor Conveyors

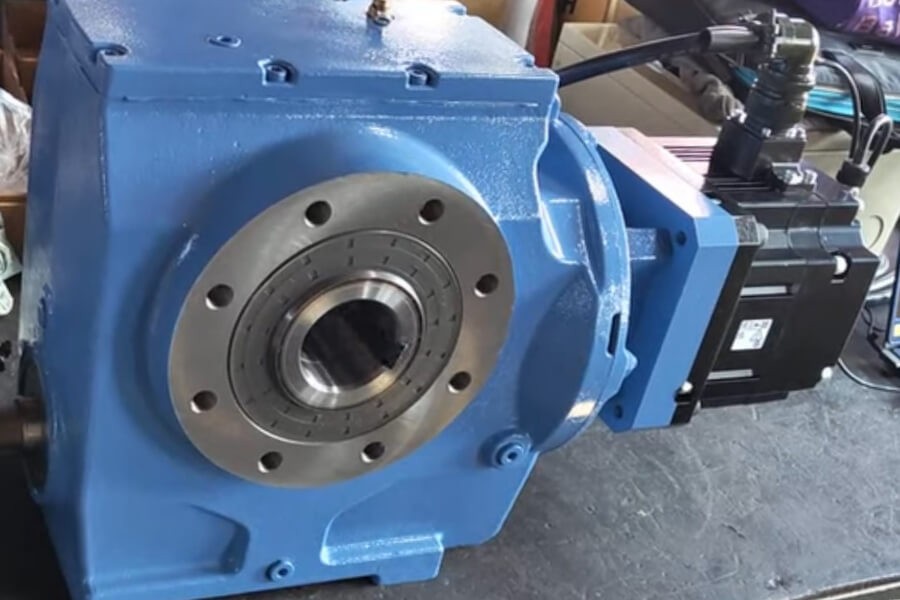

When you need high precision gearboxes for semiconductor conveyors, combining a Transcyko gearbox with a high quality Mitsubishi electric servo motor is the perfect solution for stop-start and continuous operation in semiconductor manufacturing. This Transcyko design includes a customized fail-safe manual override system to allow safe removal of in-process components in the event of power failures.

How are precision conveyors used in semiconductor manufacturing?

Taiwanese semiconductor manufacturing leads the world in quality and performance, and precision semiconductor conveyors are an integral element of semiconductor production. Semiconductor manufacturing conveyors are used to safely transport in-process and finished silicon wafers and components between production stages, and also to ensure precise location of components in some automated manufacturing processes.

Why are Transcyko gearboxes perfect for semiconductor conveyors?

- Very precise control of semiconductor conveyor movement

- Fail-safe manual override in the event of power failure

- Clean, sealed construction to prevent environmental contamination

- Compatibility with existing semiconductor conveyor systems and equipment

- Modular design to accept client’s choice of motor systems

- Flexible flange and alignment options to allow for any orientation

- Dependable replication of gearboxes & motors for uniform performance

- Exact quality control standards for guaranteed reliability

- Easy maintenance with minimal disruption to production

Semiconductor manufacturing takes place in clean, vibration controlled environments due to the nanoscale accuracy required. The quality standards for components that contribute to the process is very high, and this includes the use of only the best, most carefully engineered, motors and gearboxes for semiconductor conveyors.

High precision semiconductor conveyor servo gearbox design

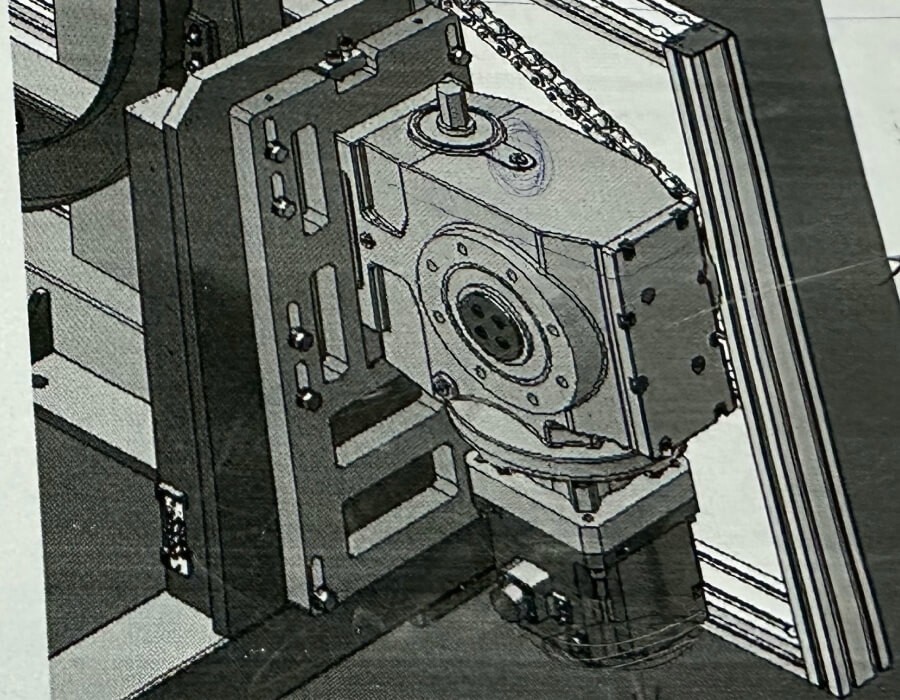

We worked with our client to supply a semiconductor conveyor motor combining a high precision Transcyko gearbox with a Mitsubishi electric servo motor to meet client requirements for precision control, clean and consistent operation. The specification included emergency manual drive customization to enable conveyors to be cleared in the event of power failure.

What are 7 typical uses of line, lift & rotating semiconductor conveyors?

- Chip assembly processes

- Semiconductor packaging systems

- Component transfer between stages

- Cleanroom compatible conveyors for wafer carriers

- Vertical lifting conveyor systems for multi-level plants

- Minimizing manual handling of delicate components

- Downstream shipping systems

Failsafe gearbox manual override to protect in-process components

The very high value of components in the Taiwanese semiconductor industry makes it essential that any unforeseen stoppages do not endanger in-process components or create unnecessary delays. Having a manual override system for operating the conveyor gearbox in the event of an electrical issue is an important feature for this essential industry.

Transcyko incorporated an effective, efficient and easily operated manual override into the gearbox and servomotor design to enable manual operation of the gearbox to clear work in progress from the conveyor without the risk of damage or contamination that might be caused by other methods of accessing the components on the conveyor belt.

Transcyko refines semiconductor conveyor gearbox design

Transcyko gearboxes and cyclo drives have been refined over more than thirty years of engineering experience. Transcyko is a leading global supplier of high quality speed reducers and gearboxes for industries that need dependable, reliable, precision conveyors and drive solutions for a wide range of technologies, from AGVs to centrifugal processing. Transcyko cycloidal gear reducers are legendary for their outstanding performance characteristics.

Transycko conveyor gearboxes are offered with a very wide range of mounting and flange options to give you drop–in compatibility with your existing conveyor systems, including component parts for maintenance and servicing. Transcyko offers customized designs and hybrid products for specific industry applications of our advanced gearbox technologies. Contact us to discover the Transcyko solution to your conveyor gearbox needs.