Transcyko Installs Liebherr LGG 700 Grinders for Precision Gearbox Manufacturing

Transcyko installs new Liebherr LGG700 grinder for precision beveloid gearbox manufacturing. The new grinder installation consolidates our capabilities to manufacture compact, high quality gearboxes for a wide range of industrial applications.

Precision beveloid gear grinding is essential for high performance gearbox manufacturing

Transcyko is a leading manufacturer of high performance gearboxes and depends on precision beveloid gear grinding to maintain our competitive advantage. Continuous generating grinding is the standard method of shaping the beveloid gears used in high performance, compact, gearbox manufacturing.

The quality of generating grinding depends on the tolerances of the grinding machine as well as the use of appropriate grinding heads, forms and grinding machine programming. Liebherr is a globally recognized leader in both CNC and manual grinder manufacturing for systems designed to achieve the extremely tight tolerances required by our clients.

How versatile is the Liebherr LGG 700 grinder for gearbox manufacturing?

The Liebherr LGG 700 grinder shown being delivered in the video above is a versatile CNC grinder that is capable of generating grinding, profile grinding and internal grinding in one machine. Transcyko employs all three types of CNC grinding in our precision gearbox manufacturing processes, and this made the Liebherr LG700 a logical choice to meet the needs of our customers for extremely high quality standards.

Universal machines improve gearbox manufacturing efficiency

Liebherr excels at manufacturing universal machines, and the LGG 700 is no exception. With it’s combination of multiple grinding capabilities alongside ease of use features for both custom projects and mass production it is a very useful addition to the Transcyko stable of high performance, high efficiency gearbox manufacturing technologies.

Transcyko gearbox manufacturing automation

The ease of operation of the Liebherr LGG 700 is another attractive feature for Transcyko beveloid gearbox manufacturing. The integrated CNC systems of the LGG 700 include context-sensitive user guidance and continuous process monitoring, which improves operating safety standards and optimizes the speed of operation for gearbox manufacturing automation.

What are the three grinding processes that Transcyko uses for gearbox manufacturing?

- Generating grinding

- Profile grinding

- Internal grinding

What is generating grinding?

Generating grinding is a high-precision process for hard-finishing gears in which a grinding wheel with a worm-drive profile rolls against the gear while grinding. This is an efficient way of creating accurate tooth profiles for beveloid gears.

What is profile grinding?

Profile grinding uses a grinding wheel that is dressed to the exact profile required for the finished product. This profile is replicated in the workpiece in the grinding process. This enables the grinding of contours, curves, and complex shapes with high accuracy.

What is internal grinding?

Internal grinding is also known as ID (Internal Diameter) grinding, and is used to grind the internal surfaces of a workpiece that has holes or tubular features. Internal grinding is very useful for improving the surfaces of CNC machined or drilled holes and bores.

Why are beveloid gears used in gearbox manufacturing?

Beveloid gears are used for gearbox manufacturing when you want to reduce shaft angles for angle drives or eliminate backlash in parallel shafts. Any complex, conical involute gears that need to be driven on non-parallel or offset axes will require beveloid gears. It is almost impossible to make highly compact gearboxes without using beveloid gears.

What types of advanced gears can Transcyko manufacture?

- Asymmetric profile gears for unequally distributed loads & increased power density

- Beveloid gears for reduced shaft angles and zero backlash designs

- Cycloidal gears for extreme reliability and shock resistance

- Customized free-form flank gears for highly specific applications

- Precision double helical gears from high strength materials

What size of gears can Transcyko manufacture with the Liebherr LGG 700?

The Liebherr LGG 700 is used for grinding gears with a workpiece diameter between 300 and 700mm and efficient grinding capabilities up to module 14. Transcyko has the capacity and technology to manufacture gearboxes with gears of all types, and the LGG 700 adds additional options for CNC machining of high precision heavy duty gearboxes in sizes that are commonly used by many industries.

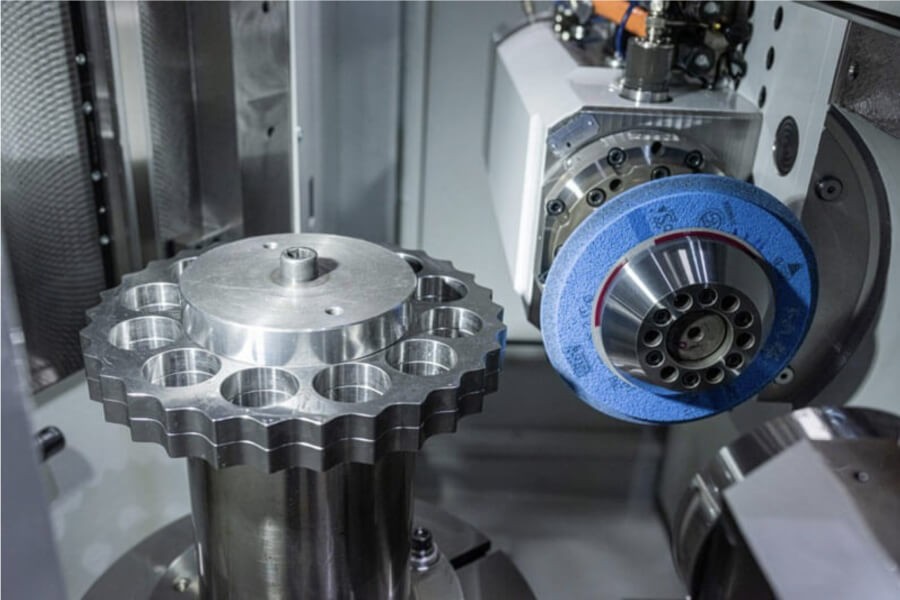

Can the Liebherr LGG 700 be used for Transcyko cyclo gearbox manufacturing?

Cycloidal gearbox manufacturing requires dimensional precision, high-quality surfacing, excellent profile and pitch, and rollers that fit perfectly to the inner ring. The Liebherr LGG 700 adds to our existing capabilities using the Kapp Niles KX 500 Flex, pictured above, and makes it possible to produce cam disks with an external gear via generating grinding. This offers an additional grinding method for Transcyko cam disks for Transcyko cyclo gearboxes.

Why should you choose Transcyko for beveloid gearbox manufacturing?

Transcyko has been manufacturing speed reducers and gearboxes for many decades to the highest quality control standards, and our latest investment in Liebherr technology extends our existing capabilities in manufacturing gearboxes by increasing efficiency and production volume capabilities.

Transcyko manufactures gearboxes, gearbox assemblies, speed reducers, drives, spare parts and components. The needs of our global customer base range from industrial centrifuges and coal power conveyors to precision gearboxes for semiconductor manufacturing.

We can design, prototype and manufacture customized ODM solutions for your gearbox needs, and also provide efficient drop-in replacements for Sumitomo, Zambello, Bonfiglioli and SEW Eurodrive gearboxes. Contact us to discuss how our expertise can be put to work to supply your industrial gearbox requirements.