Planetary vs Cycloidal Gearboxes

Understanding the differences between cycloidal gearboxes and planetary gearboxes

Cycloidal gearboxes are compact, powerful and rugged, and are used in a wide range of industrial and commercial applications. Planetary gearboxes can also generate high torque, and are also commonly used by all sorts of business, so how do you choose between them?

Transcyko are experts in matching our planetary gearboxes and cycloidal gearboxes to the general and specific requirements of our global customers. Because we manufacture cycloidal gearboxes and planetary gearboxes, our customers frequently ask us what the difference is between them and which type would be best for them, so let’s see if we can answer these questions!

We’ve been making gearboxes for forty years, so we think it’s pretty obvious what the differences are, but we want our customers to feel as informed as possible when they come to make decisions about the best way to meet their needs.

How do planetary and cycloidal gearboxes compare?

There are a huge number of different machines on the market. This means that even though each one is best suited for a specific type of gearbox it can be difficult to explain why. That’s why we’ve put together a table to compare planetary and cycloidal gearbox features and capabilities for a gearbox of the same physical dimensions.

| Feature | Cycloidal | Planetary |

| Reduction Ratio | Higher | Lower |

| Torque Capability | Lower | Higher |

| Movement Precision | Higher | Lower |

| Durability | Higher | Lower |

| Maintenance | Lower | Higher |

| Noise Level | Lower | Higher |

| Contact Surfaces | Higher | Lower |

We can see immediately that the cycloidal gearbox seems to win over the planetary gearbox in every category except torque capability. Although a cycloidal gearbox is more durable and can resist very high torque loadings, it is not able to transmit as much torque as a planetary gearbox of the same size.

Remember, it does depend on the application to decide which of the characteristics is really important. The high movement precision of cycloidal gearboxes makes them perfect for stop-start servo motors, but if you don’t need high precision a planetary gearbox will work just as well.

Cycloidal gearboxes have a smaller footprint than planetary gearboxes, so if you have plenty of space you can use a bigger planetary gearbox to get the reduction ratio you need, even if you could use a smaller cycloidal gearbox for the same job.

It sometimes might be more cost effective to use a bigger standard planetary gearbox instead of a high performance, compact, cycloidal gearbox. Consider how the relative features work for your own application before making a decision. Of course you can always contact us to help you work out your requirements!

If gearboxes were cars

If gearboxes were cars, planetary gearboxes would be old, classic sports cars with big engines, able to put out lots of power, but also needing a lot of care and maintenance to keep them running. The cycloidal gearbox would be a modern, reliable, fast electric vehicle. Quick off the starting line, surprisingly compact and versatile, and easier to park in small spaces.

If you want to go really, really fast, an electric car is an excellent choice, but if you want the highest levels of torque output the old classic sports car will provide you with what you want, although it will need more maintenance and is more likely to break down. The same is true for gearboxes, if you want more torque then a planetary gearbox may be a good choice, but if you want more speed and reliability then a cycloidal gearbox will be a better choice.

How do planetary gearboxes and cycloidal gearboxes work?

Both planetary gearboxes and cycloidal gearboxes do the same thing, they convert the rotational movement of an input shaft into rotational movement at the output at a different speed. The change in speed between input and output changes the torque that the gearbox provides at the output.

Planetary and cycloidal gearboxes differ in the way the internal components convert the inputs into outputs:

- Cycloidal gear elements roll around each other

- Contact surfaces between cycloidal gears are large

- Forces are distributed evenly through the cycloidal gear system

- Planetary gear elements engage a small number of teeth to move each other

- The movement of planetary gears is called ‘swiping’

- Contact surfaces in planetary gear systems are small

- Forces in planetary gear systems are concentrated where teeth connect

What’s inside planetary gearboxes?

Planetary gearboxes (also known as epicyclic gearboxes) have three characteristic elements: the sun gear, multiple satellites or planet gears, and an inner ring gear. The input shaft drives the Sun gear, which drives the rotational motion of the planet gears, which rotates the inner ring gear.

Gears in a planetary gearbox rotate on pins embedded in a metal plate called the planet carrier, which rotates the output shaft. The output shaft has a slower rotational speed and higher torque than the input shaft.

This makes planetary gearboxes good for:

- High transmission ratios

- Significant power transmission

- Smaller dimensions than linear gearboxes

- Lower mass than linear gears when stacking for high reduction ratios

How do cycloidal gearboxes work?

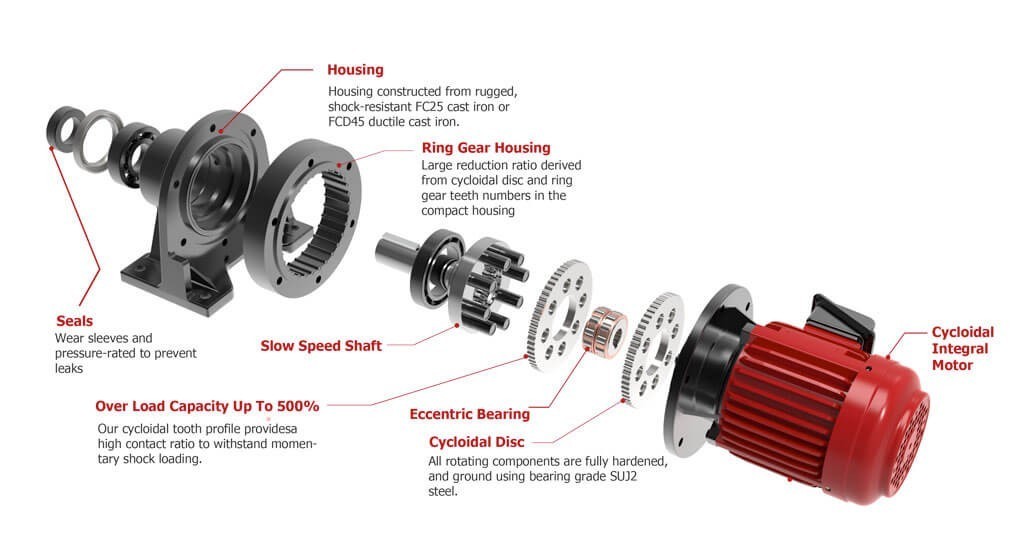

Torque transmitted to the high speed shaft rotates the eccentric cam and roller bearing assembly, and rolls the cycloid discs around the internal circumference of the stationary ring gear housing.

The teeth of the cycloid disc contact the pins of the stationary ring gear, producing a reverse rotation at a reduced speed. Each rotation of the high speed shaft advances the cycloid discs a distance of one tooth pitch in the opposite direction.

The reduced rotation of the cycloid discs is transmitted to the output shaft assembly by means of drive pins and rollers, that are projected through holes located around the bore of the cycloid discs.

Cycloidal gearboxes, cyclo reducers and derivatives are cyclo drives used for hard wearing industrial applications because they are not as susceptible to sudden failures as toothed gears, are low maintenance and easily sealed.

Cycloidal gearboxes are very good for:

- Mission critical machinery

- Extreme working environments and weather conditions

- Very high positional accuracy

- Servo systems, stop-start applications

- Sudden high torque loadings

What major industries depend on cyclo drives?

- Automotive Manufacture

- Production Line Conveyors

- Parcel Handling

- Automation

- Robotics

- Food Processing

- Textile Manufacture

- Laminating Machine

Transcyko: the one-stop solution for your cycloidal gearbox needs

We offer our customers the benefits of meeting all their gearbox requirements from us as a single source. Our high performance, reliable, speed reducers, cyclo drives, and cyclo derivatives will meet any possible requirement you have. In addition, Transcyko products feature cross-compatibility with other high performance brands for ease of service and maintenance.

- Cycloidal gearboxes

- Conventional gearbox solutions & planetary gearboxes

- Servo, travel motor, and automation gearboxes

- Cyclo speed reducers & cyclo drives

Three reasons to choose Transcyko for gearboxes, drives & speed reducers

- We are a one-stop provider for all types of gearboxes, drives and speed reducers

- Our service, support and maintenance is responsive and professional

- We service and supply parts for other leading brands of cycloid drive

Contact us to discover how we can add value to your business with our cycloidal gearboxes and drives. Our customer service team is always happy to provide expert answers to your queries.