Cycloidal Gearboxes For Food, Grain & Rice Industries

Cycloidal gearboxes are the logical choice for harsh environments and varied tasks in food, rice & grain manufacturing and processing.

What are significant applications of cycloidal gearboxes in the food, grain & rice industries?

- Grain elevators

- Screw conveyors

- Mixers, Grinders & Beaters for food processing

- Pumps for moving liquids

How do cycloidal gearboxes work for the food, grain & rice industries?

Cycloidal gearboxes, cyclo gearmotors, cyclo reducers and derivatives are cyclo drives that are ideal for operating the wide range of commonly used equipment needed in the food, rice and grain manufacturing and processing industries.

The high torque, low maintenance, easily-sealed and compact configuration of cycloidal gearboxes makes them the ideal choice for grain silo and rice conveyors and elevators, because these need to run reliably in harsh conditions without frequent maintenance.

Cyclo drives are commonly used for compact and powerful food mixing and processing tasks as well as precision automated stop-start food processing conveyors. This is because they are easily controlled with the very high positional accuracy required for servo motor applications.

How reliable are cycloidal gearboxes?

Cycloidal gearboxes are extremely reliable, which makes them very attractive in industries that demand cost leadership and have low profit margins. In the food, grain and rice industries you cannot afford expensive delays from equipment failures and unscheduled maintenance.

Cycloidal gearboxes have very even and predictable wear patterns that enable preventative maintenance to be scheduled for low demand periods. Cyclo drives and speed reducers very rarely suffer from sudden failures, giving you more peace of mind in daily food, rice and grain processing and manufacturing.

How are cycloidal gearboxes used in the food, grain & rice industries?

- Production lines

- Automated processing conveyors

- Elevators

- Grain conveyors

- Rice conveyors

- Mixers

- Cleaning

- Toasting

- Blenders

- Pumps

- Beaters

- Flaking

- Pulverizing

- Screw conveyors

Transcyko cyclo drives offer you a worry-free choice for all of these applications. Cycloidal gearboxes and cyclo derivatives offer an efficient go-to standard. This reduces maintenance costs for food manufacturing, grain and rice storage and processing by increasing reliability and standardizing spare parts.

Four benefits of using cycloidal gearboxes in the food, rice & grain industries

- Versatile and flexible installations allow for a wide range of uses

- Standardized drives reduce site maintenance costs and reduces downtime

- Cyclo drives are very powerful and compact with a small footprint

- Cyclo drives and cycloidal gearboxes are easily sealed to avoid contamination

Cycloidal gearboxes offer versatile & flexible installations

The versatility and flexible installation options of Transycko cyclo drives are an attractive feature. Our advanced designs feature cross-compatibility with other cyclo brands, including direct replacement for Sumitomo cyclo drives. Our responsive and cost-effective spare parts and servicing support also includes maintenance of other brands of cyclo drive.

Standardized cycloidal drives reduce maintenance and service costs

Cycloidal gearboxes are stronger and more reliable than conventional drives of a similar rating. This means compact, rugged, cyclo drives can be used for different types of equipment on the same site. Using fewer different cyclo drives across a site enables hot-swapping for less maintenance downtime and reduces spare part inventory.

Cyclo drives are compact and powerful with a small footprint

Short cyclo drives offer the same or better performance as conventional gearboxes with a much larger form factor. This is because conventional drives and gearboxes have to be heavily built to withstand point loadings on individual drivetrain components, requiring much heavier gears and shaft sizes to withstand shock loadings that cycloidal gearboxes manage with ease.

Cycloidal drives are easily sealed to avoid contamination

The compact size and entirely internal mechanical components of cycloidal gearboxes makes them very easy to seal and operate without any possibility of oil leaks or other forms of contamination that are unacceptable in the food and grain industries.

How do you specify cycloidal gearboxes for food & grain industry uses?

How do I select a cyclo gearmotor or cyclo drive?

For cyclo drive selection you need to identify the required output shaft motor horsepower and/or torque. The high efficiency of cycloidal gearboxes over a range of reduction ratios usually means you can maintain output shaft torque but reduce input power and use a motor with a lower HP rating.

What information do I need to select a cyclo drive?

- Motor speed (RPM) and horsepower (HP)

- The type of machine being driven by the cyclo drive

- Reduction ratio

- Type of mounting: vertical, horizontal, right-angle, or other.

- How many hours per day it will be operational

- Environmental exposure or other specialized requirements will also be useful in determining specific construction details

How are service classes defined for cyclo gear motors & cyclo drives?

AGMA-defined Service Classes are applied to rate cyclo gearmotors for defined operational loading conditions. AGMA Service Classifications for gearmotors are: uniform (I), moderate shock (II), and heavy shock (III). These classifications enable you to fit your product selection to specific tasks.

It is important to check the AGMA Class recommendations of your installation to ensure you match your drive choices correctly, especially when using non-cyclo gearboxes. Using an AGMA Class I or II planetary gearbox for an AGMA Class III operation will almost certainly result in rapid, and sudden, equipment failure.

What are the AGMA classes for food & grain industry applications?

In the food, rice and grain industries, most equipment will be AGMA Service Class II, to withstand moderate shock loadings. Site transport conveyors and screw conveyors may be AGMA Service Class I, especially for food transport lines. AGMA Service Class III might be required for high torque applications such as blending of very viscous or semi-frozen materials like treacles or ice-cream.

Some commonly asked questions about cycloidal gearboxes

How much shock loading can a cycloidal gearbox take?

Cycloidal gearboxes and drives withstand momentary shock loadings of 500% of rating. Conventional gearboxes can suffer from shaft or gear failures at shock loads of 300% of rating. We can design customized cyclo drives for specialized applications that require more than 500% overload capacity.

How fast are the standard input speeds for cyclo drives?

Standard cyclo motors operate at 1750 and 1165 RPM input speeds at 60hz. This is equivalent to 1450 and 980 RPM at 50Hz. Our technical experts are happy to work out any non-standard input speed requirements you may have. These will require calculations to work out how it will affect gearbox torque and horsepower ratings.

Are cyclo drives limited by thermal capacity?

The simple answer is no, because cyclo drives are almost frictionless, their thermal rating is usually higher than can be generated by their mechanical capacity. Even when they are worked very hard, cycloidal gearboxes do not suffer from conventional heat limitations because the unique design shares loads across internal gear components.

What inverter turn-down ratio can we supply?

A 10:1 ratio is standard for unbraked motors. Braked motors may be limited to 4:1 or better depending on power rating. A 1000:1 ratio is possible for C-face configurations.

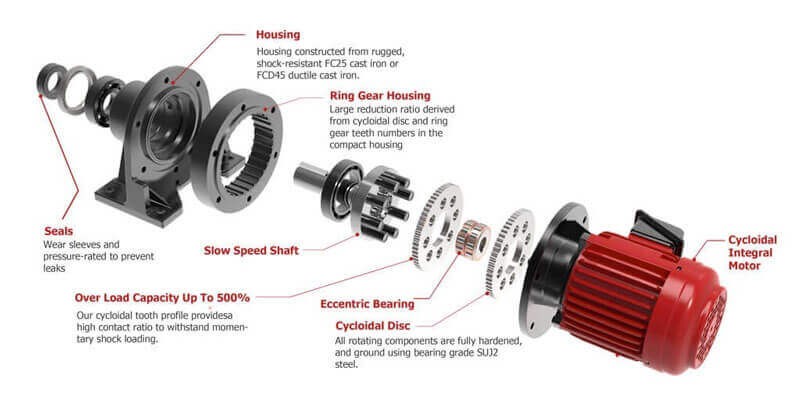

Key Features of Transcyko 600 Series Cyclo Drives

- Wear sleeves and pressure rated seals ensure excellent sealing of the cycloidal drive even in harsh conditions.

- Casings constructed of rugged, shock-resistant FC25 cast iron or FCD45 ductile cast iron.

- Reduction gearing is contained in a compact ring gear housing for high power density enabling large reduction ratios.

- Fail-safe service as stresses are shared across 60% of component parts during operation, compared to 5% or less for conventional drives.

- Rotating components are vacuum degassed, hardened bearing grade SUJ2 steel for consistent and reliable performance.

- Output shafts can be customized to any size or material requirement.

- Overload capacity withstands momentary shock loads of up to 500% of normal operational range.

Transcyko offers a one-stop solution for your gearbox, drive & speed reducer needs

Our customers benefit from being able to achieve all their gearbox requirements from us as a single source. The Transcyko range of high performance, reliable, drives, speed reducers and gearboxes covers every possible application you may have. Transcyko products also feature cross-compatibility with other leading brands for easy one-stop service and maintenance.

- Cycloidal gearboxes

- Cyclo drives & speed reducers

- Planetary gearboxes and conventional gearbox solutions

- Travel motor, servo and automation gearboxes

Why is Transcyko the logical choice for all your gearbox, drive & speed reducer needs?

- We are your one-stop provider for all styles of drives, speed reducers, and gearboxes

- We can supply and service parts for other high performance brands

- We offer quick and effective servicer support and maintenance

Contact us today to see how our cyclo drives will meet your food, rice and grain industry demands. Let us help you add value to your production systems, improve cost leadership and improve on-site reliability. Our customer service team is always ready to offer a friendly and expert response to your enquiries.