Cyclo Drives For The Clay Working Industry

High torque, shock resistance and durability make cyclo drives the perfect choice for demanding clay working applications

Durable Cyclo Drives In The Clay Working Industry

For clay mining applications, the durability and reliability of Cyclo drives is a significant benefit. Open cut clay mining exposes pumps and conveyors to weather, dust, and abrasive slurry. This will rapidly wear out the internal components of conventional drives, requiring frequent maintenance.

Cyclo drives are compact, and offer an easily sealed, versatile option that is ideal for both specialized clay working machinery and the general transport and pumping tasks necessary to maintain mining operations on any scale.

How are cyclo drives used In the clay working industry?

There are ten major applications of cyclo drives in the clay working industry, for both specialized and general use. These are:

- Brick Press

- Briquette Machines

- Conveyors

- Elevators

- Escalators

- Clay Working Machinery

- Pug Mills

- Stone Crushers

- Gravel Pumps

- Kiln Dryers

Transcyko cyclo drives and cyclo derivatives are an excellent first choice option, or can be retrofitted as a trouble-free alternative to existing conventional gearboxes, drives and reducers.

Robust cyclo drive designs are easy to maintain

Cyclo drives are highly resistant to shock loadings because they share loads internally, unlike conventional gearboxes, which often fail under shock load because the stress is focused on single shafts and gears.

It is very unusual for a cyclo drive to fail without warning due to shock loading, and this enables the planning of predictable and convenient maintenance intervals to suit the requirements of your business.

How using standardized cyclo drives saves time & money

Because cyclo drives are versatile, compact, and able to withstand significant torque and shock loading, it is often possible to use a standard cyclo drive model for many different clay working applications, especially conveyor and transport systems.

There are three benefits of using standardized cyclo drives instead of conventional drives:

- Standardization saves time by enabling drives to be swapped out for easy maintenance and repair without halting production.

- Standardization saves money by reducing the need to keep a large number of different parts in stock for maintenance and servicing.

- Fewer different sizes of gearboxes or reducers are required.

Cost effectiveness of cyclo drives in the clay working industry

The compactness, high power rating, and greater efficiency of Transcyko cyclo drives compared to conventional gearboxes means a shorter cyclo drive can offer the same power and torque output as a significantly larger, and more costly conventional gearbox.

It is easy to standardize cyclo drives for multi-use across different types of commonly used equipment in a mining and processing facility. This adds benefits from uniform maintenance and a smaller parts inventory.

Major efficiency gains in the clay working industry can be achieved by using smaller cyclo drives and fewer different models of drive across a mining or processing site because this simplifies maintenance and parts management.

Selecting A Cyclo Drive For Clay Working Industry Use

How do I select a cyclo gearmotor?

The selection of suitable cyclo gearmotors depends on motor horsepower and/or torque requirements measured at the output shaft. Cyclo gearmotors are extremely efficient over a wide range of reduction ratios. This usually means input power can be reduced, and a motor with a lower HP rating can be used, without losing output shaft torque.

What information do I need to select a cyclo drive?

To identify the correct cyclo drive for your needs, you will need to evaluate:

- The application: what type of machine is being driven

- Expected daily hours of operation

- Motor horsepower (HP) and speed (RPM)

- Mounting type: vertical, horizontal, right-angle…

Make a note of any specialized requirements including environmental exposure, as this will be useful in determining specific casing and construction details.

How are Service Classes used for cyclo gear motors & drives?

AGMA-defined Service Classes are applied to rate cyclo gearmotors for defined operational loading conditions. AGMA Service Classifications for gearmotors are: uniform (I), moderate shock (II), and heavy shock (III). These classifications enable you to fit your product selection to specific tasks.

In the clay working industry, most specialist applications, such as brick presses or crushers, are AGMA Service Class III, with high shock loadings. The majority of other applications in clay working are AGMA Service Class II with moderate shock loadings. Some general purpose site pumping and transport applications may fall into AGMA Service Class I.

Will a cyclo gearmotor withstand unexpected shock loads?

Cyclo gearmotors and cyclo drives are more shock resistant than planetary gearmotors by design. This is because loads are spread evenly between moving parts. Cyclo drives and gearmotors can withstand momentary intermittent shocks of 500% of the standard rating.

Planetary gearmotors are normally rated to a maximum 300% momentary shock overload. Our technical team will be happy to design a custom configuration if you expect shock loads greater than 500% of the rating.

What are the standard input speeds for cyclo gearmotors?

Standard cyclo motor speeds at 60Hz are 1750 and 1165 RPM, which equates to 1450 and 980 RPM at 50Hz. Non-standard input speeds will need to be calculated to determine how they affect horsepower and torque ratings. Our technical team are always happy to discuss any requirement.

What are the thermal capacity limitations of cyclo drives?

The smooth, almost frictionless operation (unlike traditional helical gears) of cyclo drives gives them a thermal rating that is beyond the mechanical capacity of the cyclo drive. Cyclo drives are not subject to conventional heat limitations even when worked hard because of the shared internal loadings within the drive.

What inverter turn-down ratio is available?

A 10:1 ratio is standard for unbraked motors. Braked motors may be limited to 4:1 or better depending on power rating. A 1000:1 ratio is available in a C-face configuration.

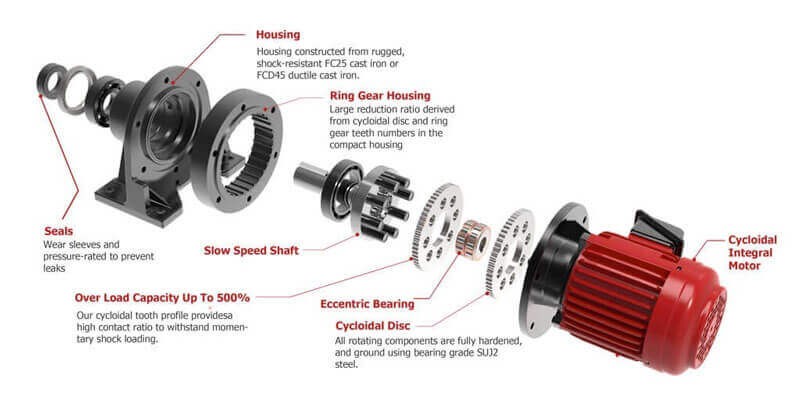

Key Features of Transcyko 600 Series Cyclo Drives

- Wear sleeves and pressure rated seals ensure excellent sealing of the cycloidal drive even in harsh conditions.

- Casings constructed of rugged, shock-resistant FC25 cast iron or FCD45 ductile cast iron.

- Reduction gearing is contained in a compact ring gear housing for high power density enabling large reduction ratios.

- Fail-safe service as stresses are shared across 60% of component parts during operation, compared to 5% or less for conventional drives.

- Rotating components are vacuum degassed, hardened bearing grade SUJ2 steel for consistent and reliable performance.

- Output shafts can be customized to any size or material requirement.

- Overload capacity withstands momentary shock loads of up to 500% of normal operational range.