Cyclo Drives FAQ

What are the Advantages of Cyclo Drives?

Cyclo drives are used in a huge range of applications and they have three key advantages over other types of drive.

- Cyclo Drives can meet very high speed requirements

- Cyclo Drives provide 24-7 reliability

- Cyclo Drives are lighter and smaller for the same power

1. Cyclo Drives are the High Speed Solution:

Flexible configuration meets any customer requirements. Cyclo speed reducers can be configured to meet customer requirements for very fast rotation speeds, and are efficient at high speeds for reduced operating costs.

Cyclo drives are more reliable and efficient at high speed than other gear types.

2. Cyclo Drives Provide 24-7 Reliability:

- Cyclo drive technology shares the load

- Cyclo drives are hard wearing and low noise

- Cyclo drives keep running when others stop

Cyclo Drive Shares The Load

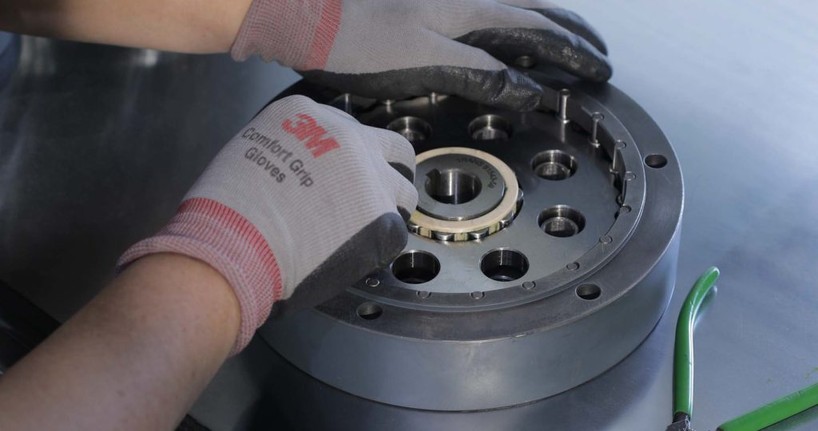

In a cyclo drive, the input shaft drives a toothed disc that rotates inside a larger housing. The teeth are always connected at many points because the disc fits closely into the housing gear. Stresses are evenly shared.

Cyclo drives are hard wearing and low noise

Large contact areas between moving parts reduces noise and wear. Low stress connections between the input and output shafts are made with steel pins sliding in channels cut in the drive disc.

Cyclo drives keep running when others stop

The smoothly shared load of Transcyko Cyclo Drives means they will keep running even if some internal parts are worn, or even broken. Other gear technologies put high stresses on small components which fail suddenly.

3. Cyclo drives are powerful, light and small

- Smaller than the alternatives

- Perfect for rapid changes in speed and stop-start uses

Smaller than the alternatives

To achieve the same capability as a cyclo drive of the same power, traditional gears must be larger and heavier.

Perfect for rapid changes in speed and stop-start uses

Reduced weight, and better load sharing design, make Transcyko cyclo designs superior perfect for rapid changes in speed, and stop-start uses.

What do our customers use Transcyko Cyclo Drives for?

- Cyclo Drive for Travel Motors for Automated Guided Vehicles

- Cyclo Drive for Production Line Conveyor Systems

- Cyclo Drive for Mixers and Agitators

- Cyclo Drive for Pumping, Cooling and Lubrication Systems

- Cyclo Drive for Metalworking Machines

- Cyclo Drive for Construction Machinery

- Cyclo Drive for Water Treatment and Recycling Plants

- Cyclo Drive for Steel Industry Production

- Cyclo Drive for Sawmills and Woodworking Machines

- Cyclo Drive for Hygienic Production Lines for the Food and Sugar Industries

- Cyclo Drive for Heavy Materials Transportation in Rolling Mills

- Cyclo Drive for Handling Equipment in the Paper Industry

Why are Transcyko Cyclo Drives the best choice?

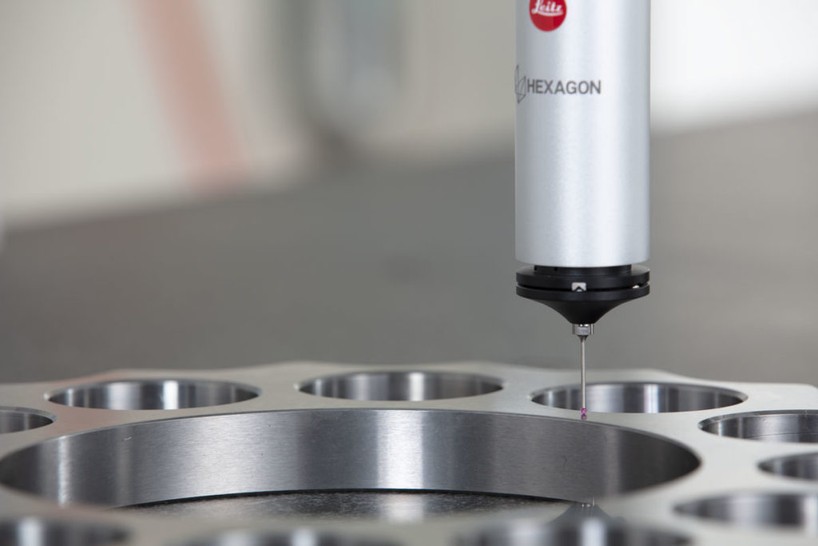

Transcyko Cyclo Drives are built to very high quality standards. We can also service and upgrade the drives of other manufacturers. High quality and excellent construction enables very high drive speeds to meet all customer requirements.

We pride ourselves on:

- Fail-safe reliability

- Brand servicing compatibility

- Very high speed ratios

Cyclo Drive – Fail-safe Reliability

Transcyko Cyclo Drives share stresses across more than 60% of parts, compared to 5% or less for conventional gears. Our drives stay in service, even if damaged, until the customer chooses a convenient time for maintenance. Transcyko Cyclo Drives are truly ‘fail-safe.’

Brand servicing compatibility

We offer the peace of mind and cost savings that come from having local parts availability for all major brands of cyclo drive. Transcyko parts can be used to service and upgrade the drives of other manufacturers.

Customisable speed ratios

Transcyko engineering designs feature single drives which easily achieve 100:1 ratios, and these can be connected in stages to achieve ratios of nearly 1,000,000:1.

Discover peace of mind for your mission-critical requirements. Contact us today about Transcyko Cyclo Drives: 24-7 reliability by design.