Chemical Industry Now Critical To Solving Global Energy Storage Challenges

Flexibility, reliability and durability of cyclo drives supports raw material processing for the battery industry

Global Energy Industry Focusing on Large Scale Battery Storage

The recent COP26 UN climate goals focus on the need for more renewable energy, and better energy storage. Global national power grids are investing in new battery storage solutions including vanadium flow technology (VFRB) to get best use from sustainable energy supplies. In the UK alone, an extra 20GWh of battery storage would reduce the waste of wind power energy by 50%.

Increasing Need For Grid Stabilization Batteries

Improved battery technology and the adoption of larger battery banks has an enormous impact on the utility of sustainables and integration of them into the electrical storage grid. Currently we see an unacceptably high level of wastage from renewable energy sources. Grid stabilization has become critically important in enabling effective renewable power production and use.

Cyclo Drives Serve New & Emerging Battery Technology

Battery technology is being driven by the need for large battery installations that are compatible with both traditional and renewable energy production. New and emerging battery industry processes require reliable drive motors that work in harsh environments and enable chemical and material processing on a large scale to meet increasing demand. Cyclo drives are the perfect choice for the wide range of demanding applications required.

Battery Manufacturing Is A Chemical Process

Battery manufacture is based on chemical processing. The battery industry uses heat and power to transform raw materials into battery electrolytes and components. To remain competitive, these processes demand cost-effective and reliable solutions. At Transcyko we manufacture efficient, durable, low maintenance cyclo drives and speed reducers to enable our customers to meet these needs.

Material Processing In Battery Manufacturing

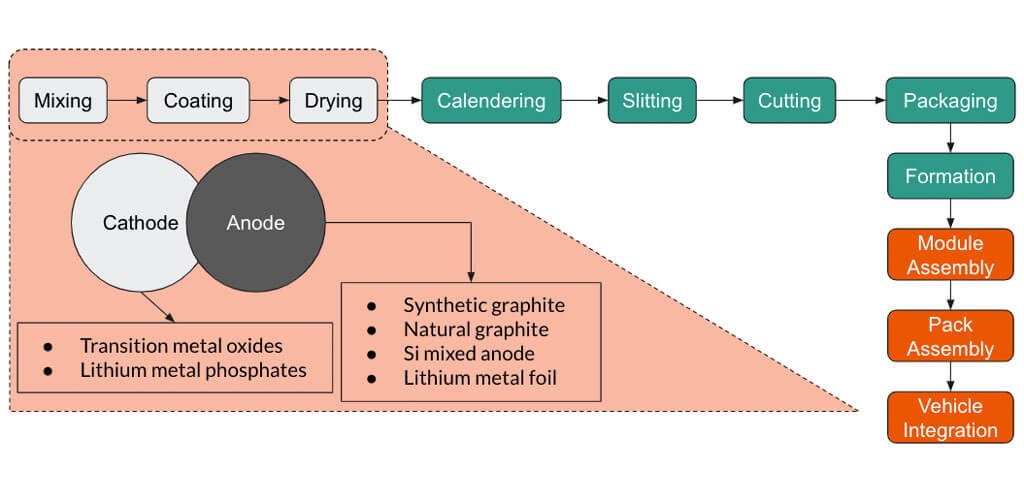

The battery manufacturing process has multiple stages that use a wide range of equipment.

Chemical Industry Applications For Cyclo Drives

Cyclo drives are very well suited to processing of the chemical raw materials used in battery manufacturing. These include cobalt, nickel, vanadium, aluminum and lithium compounds in solid, liquid and semi-liquid forms.

Chemical & material transport, filtration & separation, slurry pumping, filtering, mixing and separation of chemical constituents are all features of battery manufacturing, as well as mixing, coating, drying and calendaring.

Versatility

- Clarifiers

- Ore & Stone Crushers

- Constant or Variable Density Mixers

- Heavy, Moderate & Uniform Load Line Shafts

The high shock loading resistance and wide range of ratios available in cyclo drive designs make them highly versatile, offering a one-stop solution to a very wide range of drive and speed reducer applications.

Agitators

- Liquids

- Liquid / Solid Mixes

- Variable Density Liquids and Semi-Liquids

Cyclo drives are ideal for agitators handling liquids, liquid / solid mixes and variable density liquids and semi-liquids.

Conveyors

- Apron Conveyors

- Assembly Conveyors

- Belt Conveyors

- Bucket Conveyors

- Chain Conveyors

- Flight Conveyors

- Oven Conveyors

- Screw Conveyors

- Live Roll (Package) Conveyors

- Reciprocating Conveyors

- Shaker Conveyors

Cyclo drives are suited to a wide range of conveyors used in chemical and battery manufacturing industries, both uniformly loaded or fed and heavy duty without uniform feeds.

Cranes & Hoists

- Main Hoists

- Reversing Cranes & Hoists

- Skip Hoists

- Trolley Drives

- Bridge Drives

Suitable for medium and heavy duty main hoists, the versatility of cyclo drives makes them an excellent choice for all crane and hoisting applications.

Elevators

- Bucket – Uniform Load / Heavy Load / Continuous

- Centrifugal Discharge

- Escalators

- Freight

- Gravity Discharge

- Man Lifts

- Passenger Service Hand Lifts

Absolute reliability, high reduction ratios and excellent torque capabilities make cyclo drives come into their own when used for conveyors and elevators. Compact size and weight make them the best choice for these applications.

Fans

- Centrifugal Fans

- Cooling Towers With Induced Draft

- Forced & Induced Draft Fans

- Large Industrial & Mining Fans

- Light (Small Diameter) Fans

Whatever cooling and air circulation requirement you have in a chemical manufacturing site, there is a cyclo drive that will match it.

Feeders

- Apron Feeders

- Belt Feeders

- Disc Feeders

- Reciprocating Feeders

- Screw Feeders

Constant, reliable, high torque operation makes cyclo drives an obvious choice for all types of industrial feeder found in the chemical and battery industries.

Mills, Dryers, Coolers & Kilns

- Hammer Mills

- Rotary Mills

- Ball Mills

- Dryers & Coolers

- Kilns

- Pebble Mills

- Rod Mills

- Tumbling Barrels

Resistance to harsh conditions and wide temperature ranges as well as sealed casings for reduced maintenance make cyclo drives the most efficient option for all types of mills, dryers, coolers and kilns.

Pumps

- Centrifugal Pumps

- Proportioning Pumps

- Reciprocating Single or Double Acting Pumps

- Rotary – Gear, Lobe or Vane Pumps

Pump failure is a major problem for many chemical processing industries, and can lead to spoiled batches and serious accidents. Cyclo drives, with their famous reliability and ability to deliver constant output 24/7 are an excellent choice for all pumping systems.

Screens

- Air Washing Screens

- Rotary Screens for Stone or Gravel

- Traveling Water Intake Screens

Screening of chemical mixes, slurries, stone and gravel is a major challenge for conventional gearboxes and speed reducers, with intermittent shock loads and high torque requirements as well as the likelihood of leaks and contamination. Cyclo drives are designed to operate very reliably in this type of punishing environment.

Transcyko Cyclo: The Logical Choice For Battery Manufacturing

Heavy and intermittent load demands and the need for absolute reliability in harsh chemical environments make Transcyko cyclo drives the logical choice for all your battery manufacturing industry needs. Cross-compatibility with cyclo drives supplied by other global manufacturers make it easy to install and maintain Transcyko cyclo drive systems and swap them in to replace existing worn or unreliable drives.