TZSPR Cyclo Gearboxes for Centrifuges With Four-Shaft Drives

Transcyko TZSPR cyclo gearboxes are an efficient, reliable solution for four-shaft drive centrifuge designs of the type commonly used in waste water management and processing systems. Compatible with Sumitomo ZSPR gearboxes for centrifuges, Transcyko TZSPR cyclo gearboxes offer a simple and cost-effective drop-in alternative for new and upgraded centrifuge installations.

What are common uses of centrifuges with shaft drives?

Centrifuges with shaft drives are commonly found in wastewater and effluent management and processing facilities and systems around the world. Comparatively easy speed control and capacity for high torque operation make cyclo combination gearboxes an optimal solution for separation of mixed solids and liquids, and the rugged, low maintenance aspect of cyclo drives makes them an especially attractive option for use in these harsh and potentially hazardous environments.

What is unique about TZSPR cyclo gearboxes for centrifuges?

The TZSPR range of cyclo gearboxes is designed for centrifuges with four-shaft drives to enable independent regulated drive of the shaft and drum. Adjustment of centrifuge drum and differential speed for easier, more effective, speed and torque management makes TZSPR centrifuges ideal for applications that require rapid and responsive centrifuge control.

What are the advantages of four-shaft centrifuges over single shaft centrifuges?

Single shaft drive centrifuges have a direct mechanical connection between the motor and centrifuge scroll or drum. Four-shaft drives use multiple independently controlled shafts to independently adjust the rotational speed of the drum and conveyor scroll.

The independent speed control of the centrifuge drum and conveyor scroll by four-shaft drives gives much more flexibility in fine adjustments and control of separation processes. This improves efficiency and is especially useful for monitoring and adjusting solid and liquid separation in decanter centrifuges.

What are 5 important features of four-shaft drive centrifuges?

- Rotating components can be controlled independently of each other

- Combination of cyclo and planetary gear stages enables very high speed reduction

- Peak torque loads can be managed by the most robust elements of the system

- Independent drum and screen drives enables continuous precision control of separation

- Ideal for medium to large industrial centrifuges used in waste processing & dewatering

The combination of cyclo and planetary gear stages in Transcyko centrifuge drives allows exceptionally high speed reduction ratios combined with the ability of cycloidal gearboxes to manage very high torque loadings, which is a significant benefit of cycloidal engineering.

A four-shaft centrifuge with Transcyko TZSPR cyclo gearbox allows you to make very precise adjustments to the differential speed between the drum and the scroll. This is vitally important when very efficient and consistent separation of liquids and solids is required, and combined with the high torque capabilities of this configuration makes it very well suited for industrial sludge dewatering and waste processing applications.

Why are cyclo gearboxes used in industrial centrifuges?

Cyclo gearboxes are the logical choice for industrial centrifuges because they combine multiple desirable features that ensure consistent, reliable, operation. The stand out feature of cyclo gearboxes for centrifuges is their very high resistance to shock loads compared to other types of gearbox. This is a feature of the large contact areas of high pressure zones in cycloidal gears compared to helical gearbox designs, which concentrate loads on smaller points of contact.

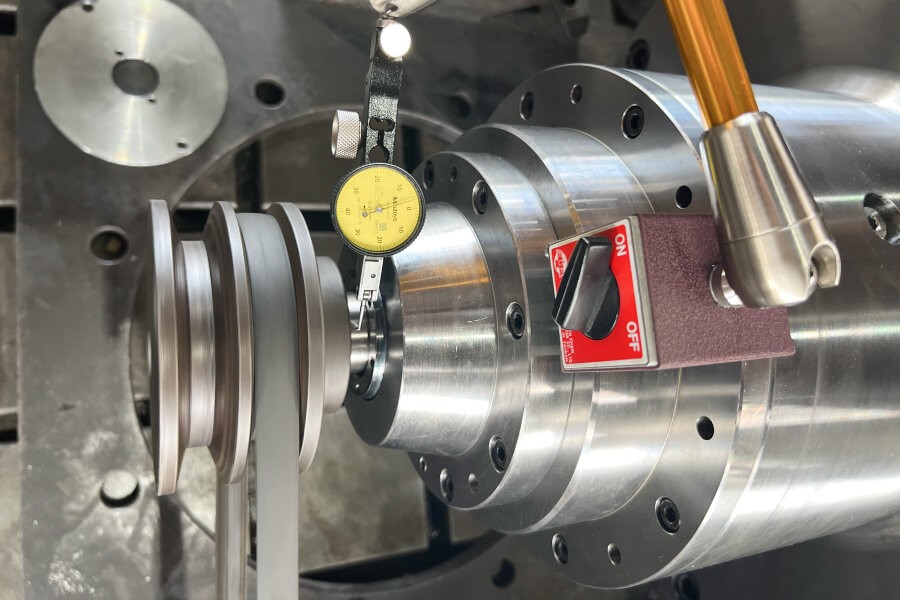

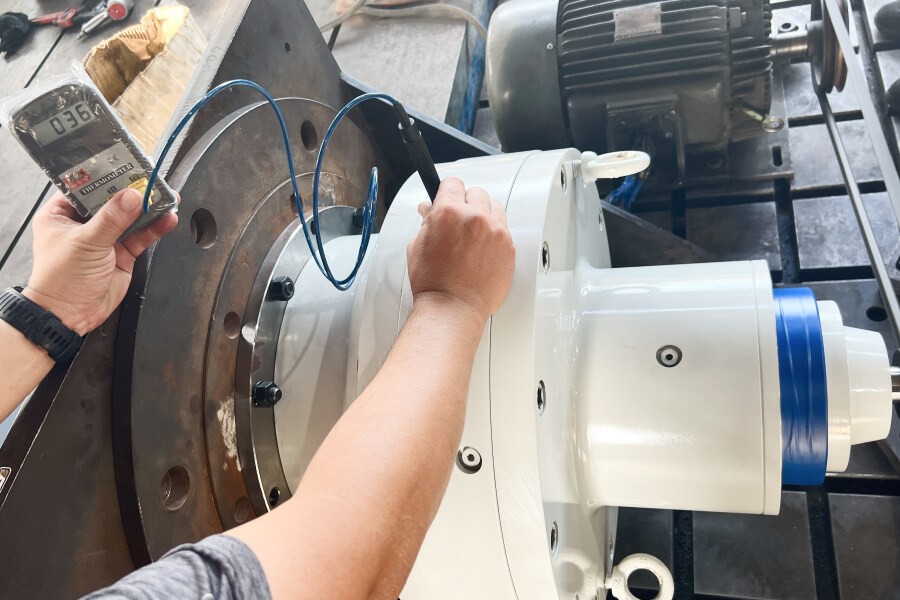

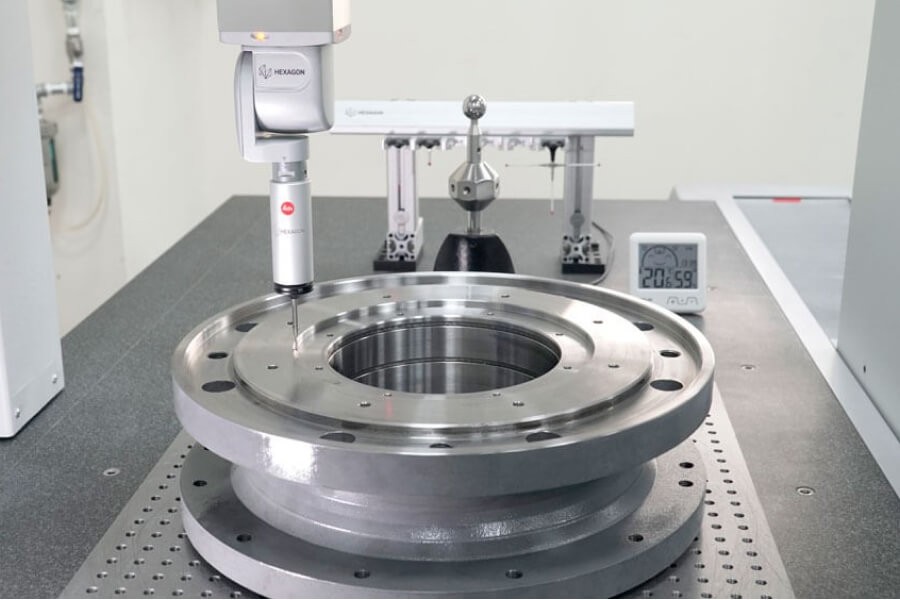

What are standard features of Transcyko cyclo gearboxes for centrifuges?

Single-stage reduction ratios from 6:1 to 87:1

Shock loading resistance to 500% of rating

Sustained output torque capabilities of 30-40,000Nm

Reliable, low noise, low wear, low maintenance designs

In house design service for custom configurations and ratios

Why are Transcyko TZSPR cyclo gearboxes your best option for four-shaft centrifuges?

Transcyko cyclo gearboxes for centrifuges offer cost effective drop-in replacements for other leading centrifuge brands, with the advantage of excellent customer service and parts compatibility to keep your centrifuge running at peak efficiency with minimal, cost-effective maintenance overheads.

What are 7 potential applications for Transcyko TZSPR centrifuge gearboxes?

- Chemical compound separation

- Dairy & food product manufacturing

- Oil & gas industry fraction separation

- Pharmaceutical compound separation & refining

- Industrial waste water treatment

- Sewage & effluent liquid separation

- Mining, mineral extraction & mineral refining

When you choose Transcyko cyclo drives and gearboxes you benefit from more than thirty years of engineering excellence. Transcyko is a leading global supplier of high quality cycloidal speed reducers and cyclo gearbox combinations for centrifuges that are depended on in critical industrial and commercial applications.

Transycko lets you choose cost effective, responsive maintenance and upgrade options for your centrifuge installations without having to rely on one specific manufacturer for support. Transcyko ZSPR cyclo gearboxes for four-shaft centrifuges are designed for drop-in compatibility with Sumitomo ZSPR gearboxes, including component parts for maintenance and servicing. Contact us to discover the Transcyko solution to your four-shaft centrifuge gearbox needs.