Twin Shaft Planetary Gearboxes For Concrete Mixers

Extreme strength and reliability makes planetary gearboxes a logical choice for concrete industry applications

Twin Shaft Planetary Gearboxes: An Industry Standard

Twin shaft concrete mixers are designed for extreme durability, and the characteristics of planetary drives make them ideally suited to these applications. Planetary drives provide reliable and consistent operation at the continuous high torque levels required for concrete mixing. This makes planetary gearboxes a very safe option for twin shaft mixers, which is why this configuration has become the industry standard.

Advantages of Planetary Gearboxes for Concrete Mixing

- Shock Resistant & Reliable

- Flexible Configurations for Ease of Installation & Maintenance

- Thorough Concrete Mixing

Shock Resistant & Reliable

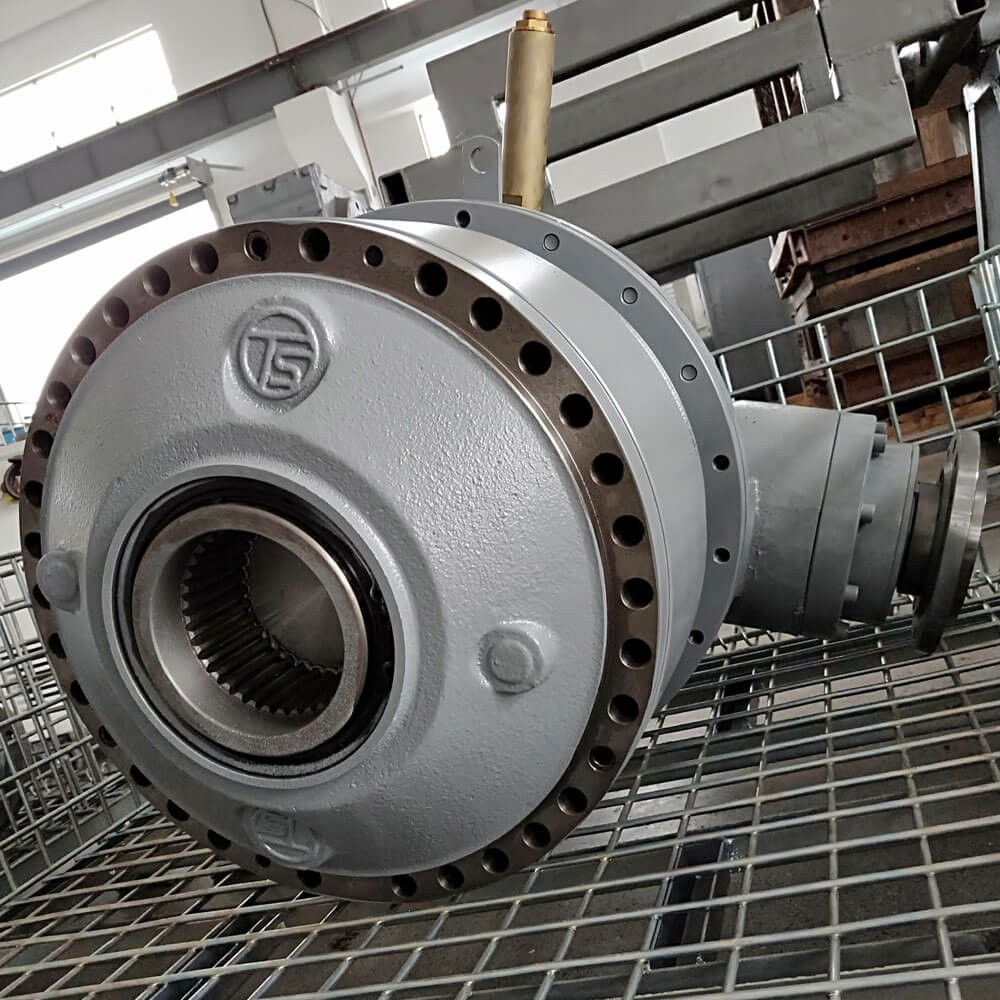

Twin shaft planetary gearboxes are compact and the planetary drive train can withstand significant shock loadings. Rugged mountings and cases make Transcyko planetary gearboxes the ideal choice for severe duty applications where impacts and shock loads are commonly encountered.

Flexible Configurations For Easy Installation & Maintenance

Our planetary gearboxes are provided in flexible configurations with different mounting options for gear arrangements, output shafts, and flange types to ensure compatibility with existing mixing machinery. Replacing your worn out or damaged gearboxes with our products is very easy regardless of the original manufacturer of your mixer. We also build our planetary gearboxes with easy adjustment and servicing in mind to make maintenance as simple as possible.

Thorough Concrete Mixing

Twin Shaft Mixers are robust and compact by design. Transcyko planetary gearboxes are perfect for enabling thorough and complete mixing of cement and aggregates, and our product range meets demands for significant output volumes and rapid mixing.

For ready mix, precast concrete, concrete blocks, pavers or dam applications, the twin shaft concrete mixer is the logical choice. Driven by our high performance planetary drives, each batch of concrete can be quickly and completely mixed.

Quality Supported by In-House Design, Manufacture & Testing

Design, testing, quality measurement and finishing work are all carried out at our premises, with no outsourcing. This ensures that our experienced technicians can achieve the highest levels of quality management without the potential faults and mistakes that are often experienced when outsourcing these functions.

Selecting A Planetary Gearbox For Twin Shaft Concrete Mixing

How do I select a planetary gearbox?

The selection of a suitable planetary gearbox depends on motor horsepower and/or torque requirements measured at the output shaft. Our drives are very efficient over a wide range of reduction ratios. This may mean that input power can be reduced, requiring a motor with a lower HP rating, without losing output shaft torque.

What information do I need to select a planetary gearbox?

To identify the correct gearbox for your requirements, you will need to consider:

- The application: what type of machine is being driven

- Expected daily hours of operation

- Motor horsepower (HP) and speed (RPM)

- Mounting type: vertical, horizontal, right-angle…

Also make a note of any specialized requirements including environmental exposure as this will be useful in determining specific casing and construction details.

Key Features of Transcyko Planetary Gearboxes

- VITON oil seals ensure excellent sealing of the planetary drives even in harsh conditions.

- Casings constructed of rugged, shock-resistant FC25 cast iron or FCD45 ductile cast iron.

- Reduction gearing is contained in a compact housing for high power density enabling useful torque ratios.

- DIN 5482 hollow output shafts as our standards for the application

- Our planetary speed reducers for twin shaft concrete mixers accommodate capacity of 1.5~4m³ concrete