Transcyko Quality Control Ensures Dependable Cyclo Drives

Cyclo Drives Manufacturing

At Transcyko we take the greatest care to match every detail of our cyclo drive systems to customer requirements. We pride ourselves on producing the best cyclo drives at affordable prices.

Our long experience in working closely with our customers is the reason why our cyclo drives offer world leading quality as well as compatibility with the widest range of machinery and equipment.

Why our Cyclo Drives are Different

- In House Manufacture

- Materials Technology

- Research and Development

- Testing and Service

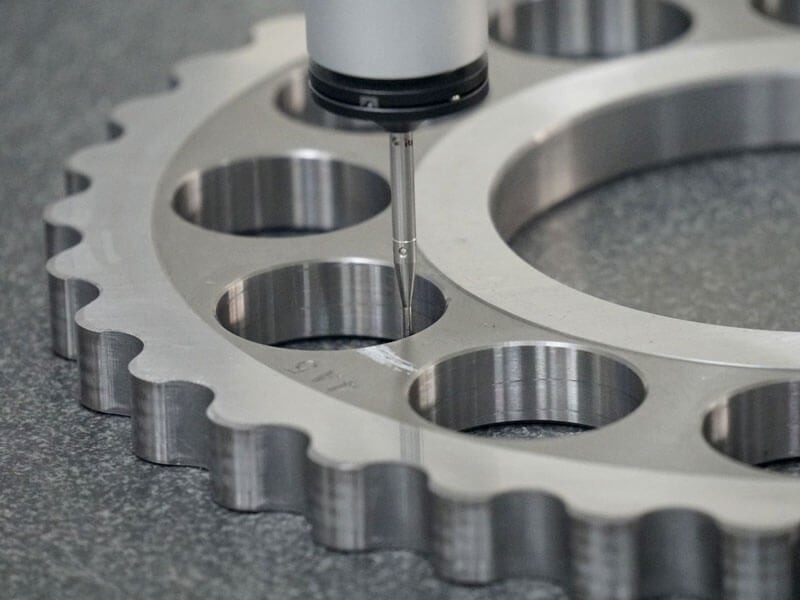

- Quality Control

In House Manufacturing Of Key Cyclo Drive Components

All key parts for Transcyko cyclo drives are manufactured in house in Taiwan. This includes cycloidal discs and eccentric bearings.

To maintain the high standards our customers require we do not risk outsourcing manufacture of specialised components to other companies that may have difficulty meeting our standards.

State Of The Art Materials Technology

Over the years we have identified the best sources for standard components, based on real-world applications and customer experience.

For bearings we use Japanese brands that have proven their reliability and suitability for purpose, and our drives feature bearings manufactured by NSK, NTN, KOYO and Nachi.

For our cyclo drive housings we use the best materials available, either FC25 cast iron or FCD45 ductile cast iron. For the cycloidal discs we use SUJ2 bearing grade steel from Japan.

In House Research And Development

We have our own in-house Research and Development team with extensive laboratory facilities to enable us to test, demonstrate and certify speed reducer performance through evidence based research.

This enables us to carry out advanced modifications to gear profiles and to develop models that are not available from Sumitomo or any other leading manufacturer. This includes our Model 622 ratio 17 and Model 621 ratio 17 6.

Unlike other manufacturers we are able to customize cycloidal speed reducers on request to any specification. We work to our customers’ requirements and do not expect them to have to compromise.

Rigorous Testing and Service Standards

With our own advanced laboratory and testing facilities, we carry out speed reducer testing under load to simulate working conditions.

This reduces the risk of failures leading to production down time. This feature of our in-house process has been invaluable in working with Mitsubishi to provide drives for their large scale sludge processing machinery.

We are able to provide material certification and other test reports upon request to offer our customers evidence that our systems will perform as expected.

Our experience in research and testing enables us to offer very fast customer support, with experts available on hand to respond to any technical queries or servicing requirements.

We keep parts in stock for immediate service and offer a response time that is significantly quicker than our competitors.

We maintain the capacity to offer servicing and support for all makes and types of cyclo drives to safeguard against production downtime regardless of the original manufacturer of your equipment.

Our designs offer cross-compatibility of parts and systems with those of other manufacturers enabling cost-effective swapping out with Transcyko cyclo drives if required.

Quality Control Builds Success

Our investment in research and development, in-house testing and certification and use of only the highest quality materials and components enables us to offer very reliable and cost-effective products and services to our customers.

At Transcyko we guarantee the highest levels of quality control to ensure reliable speed reducer performance for our customers.

Contact us now to improve reliability and add value to your production.