Transcyko Planetary Gearboxes & Servo Drives for Plastic Injection Molding

Transcyko planetary gearboxes coupled with servo drives are the leading solution for improved plastic injection molding. The helical bevel TEX series and TIN series gearboxes manufactured by Transcyko Nanjing eliminate the many issues that arise from hydraulic systems and offer simple, cost-effective, efficient drop-in upgrades for leading injection molding machines.

How does servo drive technology improve injection molding?

Advanced injection molding technology is the route being taken to improve the efficiency and profitability of plastic injection molding industries. High precision, high quality electric servo drives are the leading alternative to hydraulic systems to power a wide range of sophisticated injection molding systems. With high torque and high load capabilities and faster cycle times, servo drive injection molding delivers significant benefits over traditional hydraulic systems.

- Good for high torque / high load processes

- Up to 30% cycle time reduction compared to hydraulic systems

- Safer, quieter, more reliable technology

As an example of this technological change, servo motors as actuators for the injection molding of medical devices are now seen as the only way to achieve the precision and efficiency required for the most demanding injection molding tasks. The precision and efficiency of planetary servo drive injection molding is easily scaled to any type of injection molding process.

Which industries benefit from servo driven injection molding?

Modern servo driven injection molding machines are used for mass production of industrial and commercial goods, containers and parts, and electronic, medical and precision aerospace manufacturing. The versatility of servo driven injection molding helps engineers use new materials and techniques to improve the quality and diversify the applications of injection molding.

- What are the applications of servo driven injection molding?

- Industrial & commercial mass production

- Electronic, opto-electronic & medical components

- Precision aerospace & automotive parts

Transcyko manufactures a range of planetary single screw and twin screw speed reducers for injection molding servo motors that are excellent alternatives for hydraulic injection molding systems. We also supply drop-in replacements for other leading brands. Our planetary gear reducer servo drives are reliable and cost-effective – increasing output by reducing cycle times and offering a safer, quieter injection molding process than hydraulic alternatives.

Why are Transcyko planetary gearboxes the best choice for servo driven injection molding?

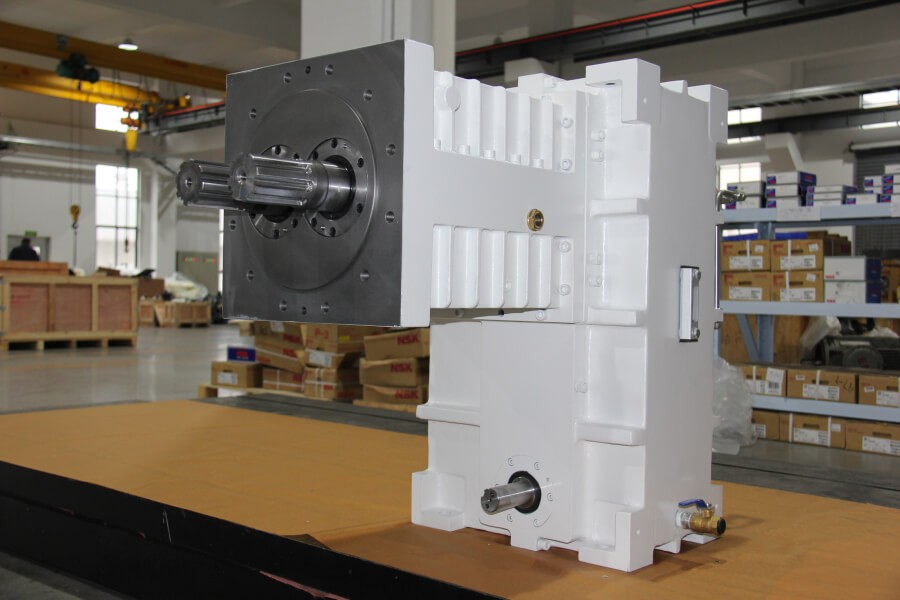

Transcyko helical bevel TEX series single screw extruder gearboxes and TIN series injection molding gearboxes offer a high quality, competitively priced, servo driven injection molding and rubber extrusion solution. The Transcyko TEX200 gearbox for plastic injection molding extruders is exclusively manufactured by Transcyko Nanjing and is the leading helical bevel single screw extruder gearbox for servo drive plastic injection molding today.

High quality, rugged alloy TEX series gears

Transcyko TEX series gears have a helical tooth design and are made of heat treated 18CrNiMo7-6 low carbon, case hardening carburizing steel. This creates an ideal balance between surface hardness and structural toughness, with high wear resistance and high fatigue life. TEX series gearboxes deliver rugged, high quality reliability under extreme pressure.

Our innovative planetary gearbox servo drive injection molding technology is scalable and adaptable for use in all types of injection molding, even replacing the high torque and load injection molding that is associated with traditional hydraulic injection molding systems.

Quieter, safer and significantly faster than older injection molding technology, Transcyko planetary servo drives reduce cycle times and increase throughput as well as energy efficiency. Our planetary servo drives are also more durable, reliable and cost-effective to maintain and service than hydraulic systems.

We offer direct drop-in replacement for Zambello and Eisenbeiss single screw extruder and injection molding gearboxes, speed reducers and servo drives. This enables rapid and efficient repairs and upgrades to your existing systems. Contact us today to discover the difference our planetary servo drive injection molding technology can make to your injection molding business.