Transycko Customized Gearbox ODM for Extended Maintenance Intervals

One of the issues facing commercial and industrial gearbox customers is the difficulty in obtaining cost effective customized gearboxes for specialized uses or use in difficult working environments where modifications to the standard design may be required to extend maintenance intervals and working life of the gearbox installation.

How does Transcyko design low maintenance gearboxes?

Transcyko gearboxes are optimized for maintenance, and our cyclo designs in particular exhibit the reduced maintenance overhead that is a feature of cycloidal gearboxes due to their large load bearing surfaces and even wear characteristics.

- Sealed gearboxes to eliminate moisture and contaminant ingress

- Cyclo gearboxes with inherent durability by design

- High quality engineering and precision gearbox manufacturing

Sealed gearboxes enable use in any environmental conditions

We can provide fully environmentally sealed gearboxes of all types, enabling them to be used in extremely harsh environments, including coal power plants or submerged in water or other liquids in waste water treatment. There are of course significant advantages to low maintenance requirements when it is necessary to immerse machinery, or have machinery that will withstand immersion, due to technical or environmental constraints.

Cyclo gearboxes are low maintenance designs with inherent durability

Transcyko cyclo gearboxes have an inherent durability and lower maintenance requirements than other types of gearboxes because they have higher shock resistance, lower operating temperatures and even wear characteristics across the geartrain. The highest wear components in cyclo gearboxes are also the easiest to access for maintenance, which is an additional bonus.

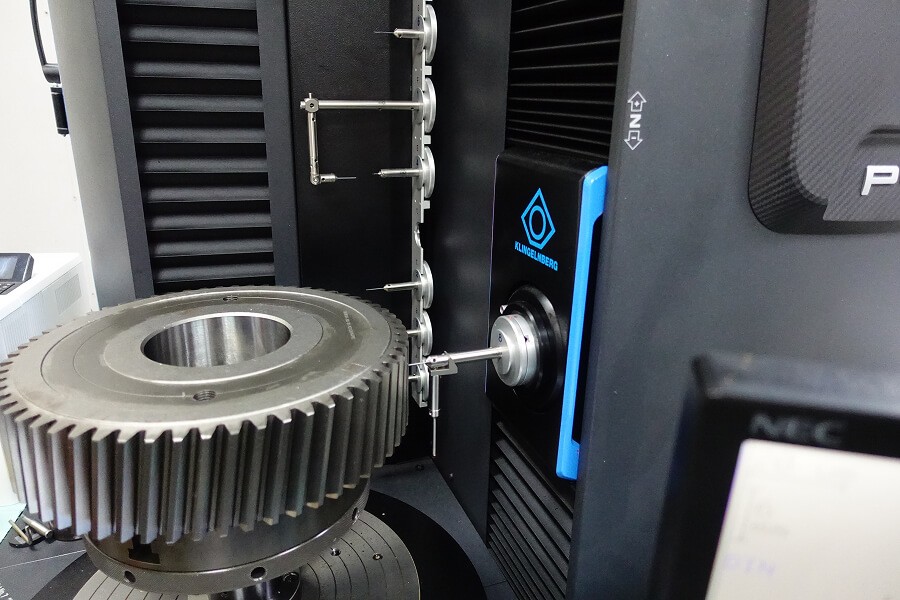

Precision gearbox manufacturing increases gearbox service life

Transcyko uses high precision CNC machining and grinding to ensure our gearboxes are manufactured to exacting tolerances for increased gearbox service life. This is not the limit of what we can do to extend the lifespan and reduce the maintenance overheads of our gearboxes, however, we also maintain a strong in-house engineering and design team who can customize our products to match specific installation requirements for low maintenance, high reliability gearboxes.

How does Transcyko ODM design expertise affect gearbox reliability?

ODM design expertise has a very strong influence on the quality of gearboxes, and increases reliability. Highly skilled and experienced engineers have the capabilities to design ODM gearboxes that are more efficient and more durable by design than simple clones of existing designs that do not take into account the numerous factors that contribute to a high quality product.

The Transcyko in-house engineering team design gearboxes to be manufactured to exact tolerances with precision fitting, with integrated knowledge of both the design and manufacturing process as well as complete familiarity with the technical capabilities of our production line. Continuous quality control processes ensure the elimination of any potential defects during manufacturing.

This is why Transcyko gearboxes have a much longer lifespan than gearboxes manufactured to slack tolerances, which experience increased wear. Longevity is also improved by manufacturing gearboxes out of higher quality alloys. A common issue with generic gearboxes is the use of lower quality components and materials that increase wear and maintenance costs.

What ODM gearbox customization canTranscyko do for inaccessible installations?

An example Transcyko ODM gearbox customization is shown in the photo above. This is a recent project for a client who needed to mount a Transcyko cyclo gearbox vertically in an inaccessible location. Transcyko cyclo gearboxes are designed to be self lubricating in any orientation, however in this situation the customer wanted to extend the maintenance schedule for as long as possible by ensuring constant high lubricant flow rates.

For this design, forced oil lubrication customization of the cyclo reducer with the inclusion of ancillary filtration and components was the most cost-effective and lowest maintenance solution for this vertical installation in a harsh environment. An additional factor is the lack of cooling water availability at the installation site, making it especially important to ensure that lubrication is effective, even though Transcyko cyclo gears have very high thermal overload resistance.

Our engineers modified the cyclo gearbox to include an additional lubrication transfer pump between the upper and lower sections of the cyclo gearbox, increasing the lubricant throughput rate and reducing the time taken for lubricant to pass through the cyclo geartrain. The result was an additional layer of reassurance and protection for our client, and an increased capacity to extend maintenance intervals to suit operational requirements.

Transcyko skills & capabilities for customized ODM gearbox manufacturing

Transcyko has more than 30 years experience of manufacturing high quality speed reducers and gearboxes for a wide range of global clients. Our vertically integrated research, design, engineering, manufacturing and testing processes gives us significant advantages in rapid prototyping and delivery of customized ODM gearboxes for any working environment.

We supply mission-critical gearboxes, gearbox assemblies, speed reducers and components to both heavy industries, including waste management, and also to the precision industries of the Taiwan semiconductor manufacturing sector. Contact us to discover how our in-depth experience of manufacturing high quality gearboxes can be used to build you the ODM customized gearbox your business needs.