Transycko Unidirectional Helical Worm Gear Reducers for Automated Material Handling

Unidirectional helical worm gear reducers are the ideal solution for high precision automated material handling systems of the type used by Taiwanese semiconductor manufacturing companies in automated material handling systems. The combination of smooth precision, reliability, and low maintenance are very attractive when you need continuous trouble-free production lines.

Why are Transcyko helical worm gear reducers used for automated material handling?

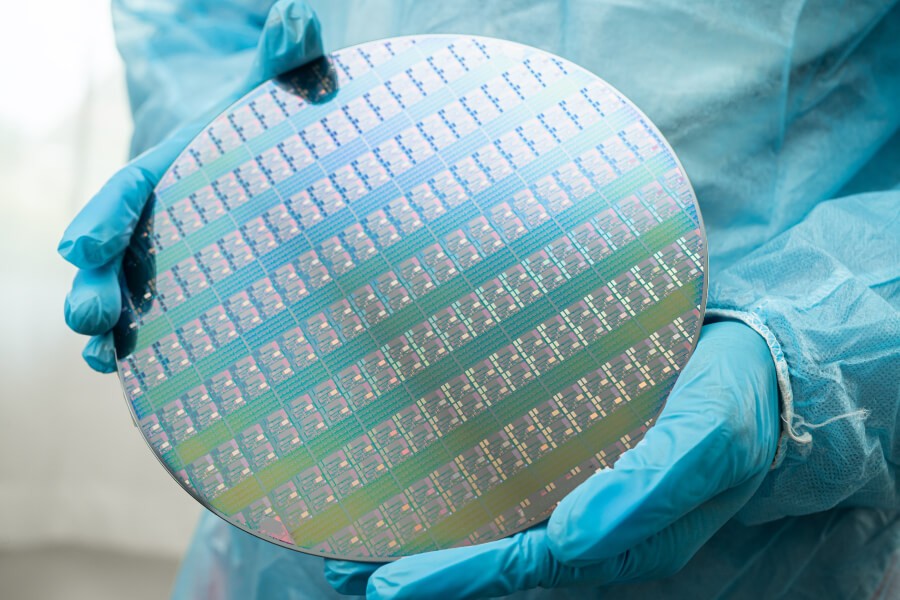

Transcyko TS Series helical worm gear reducers are ideally suited for the specific requirements of automated material handling systems (AMHS). The AMHS used for Taiwanese semiconductor manufacturing is a good example, requiring high precision unidirectional movement to ensure components are accurately moved between sequential manufacturing stations.

Reliable, high precision AMHS for semiconductor fabrication

Precision gearboxes for semiconductor conveyors fulfil an important role in contemporary semiconductor manufacturing in Taiwan. When fabrication plants and processes can extend for the equivalent of city blocks, seamless, reliable transportation of in-process components as well as completed orders is essential to maintain efficient workflow and throughput.

How are helical worm gear reducers used in semiconductor manufacturing?

- Horizontal conveyors

- Lifting conveyors

- Automated Storage & Retrieval Systems (AS/RS)

- Station to station conveyors for sequential processes

- Clean room AMHS

Low noise, smooth operation, low maintenance gear reducers

Transcyko unidirectional helical worm gear reducers exhibit extremely low vibration and noise levels, and this, combined with the inherent precision and smooth control of unidirectional helical worm gears, makes them a perfect choice for semiconductor and semiconductor component transportation. Easy enclosure and sealing also makes them a viable option for cleanroom operations, and the low stress design significantly reduces maintenance frequency and costs.

What are important features of helical worm gear reducers for AMHS

- High precision movement

- Versatile mounting options

- Manual override options

- Compatible with a wide range of motor & drive systems

- Easily integrated into existing or new system designs

- Customizable input power & output speeds

- Smooth, low noise, operation

- Low maintenance overheads

Transcyko manufactures a range of high precision gearboxes and helical worm gear reducers that are used for automated material handling. An attractive feature of Transcyko products is our ability to readily customize designs and integrate them into existing installations as upgrades as well as to combine them with any desired motor or drive system.

Typical installation for Transycko TS Series helical worm gear reducers

- Hollow shaft with key, B14 flange mounted

- Hollow shaft with shrink disk, B14 flange mounted

- Splined hollow shaft, B14 flange mounted

Transycko has a long history of manufacturing high precision gear motors and speed reducers of all types for a wide range of industrial applications. We apply this experience to perfecting and optimizing our gearbox designs and because we have a vertically integrated manufacturing capability in Taiwan, we are able to rapidly customize and adapt any model of speed reducer or gearbox to suit specific customer needs.

You can rely on Transycko gear reducers for automated material handling systems

Transcyko helical worm gear reducers are a reliable, dependable choice for all types of automated material handling systems, and can be scaled for a wide range of applications and industries. Our AHMS gear reducers are fully customizable to meet any requirement, and manufactured to our stringent quality standards using modern manufacturing technologies.

The Transyko in-house engineering and design teams ensure that any custom project is completed to the very high quality and testing standards that we apply to all our products. Our reputation for reliability and responsive customer service makes us a preferred supplier for the Taiwan semiconductor industry and other clients who need reliable precision with excellent maintenance and support. Contact us to discuss how we can satisfy your AMHS needs.