Transcyko cyclo speed reducers are used in coal burning power plant conveyors

Transcyko cyclo speed reducers are the most reliable solution for coal burning power plant conveyors of all types. Coal power plants are harsh working environments that make heavy demands on the machinery used to maintain continuous operation, and reliable conveyors are essential for delivery of fuel and removal of waste products.

Why are conveyors so important to coal burning power plants?

Any solid fuel power plant has to maintain a reliable transportation system for incoming fuel and outgoing waste products. Coal burning power plants rely on conveyors and escalators to supply a steady stream of incoming coal as fuel, and as a reliable method to remove spent fuel for processing and recycling

What is the production cycle of a coal burning power plant?

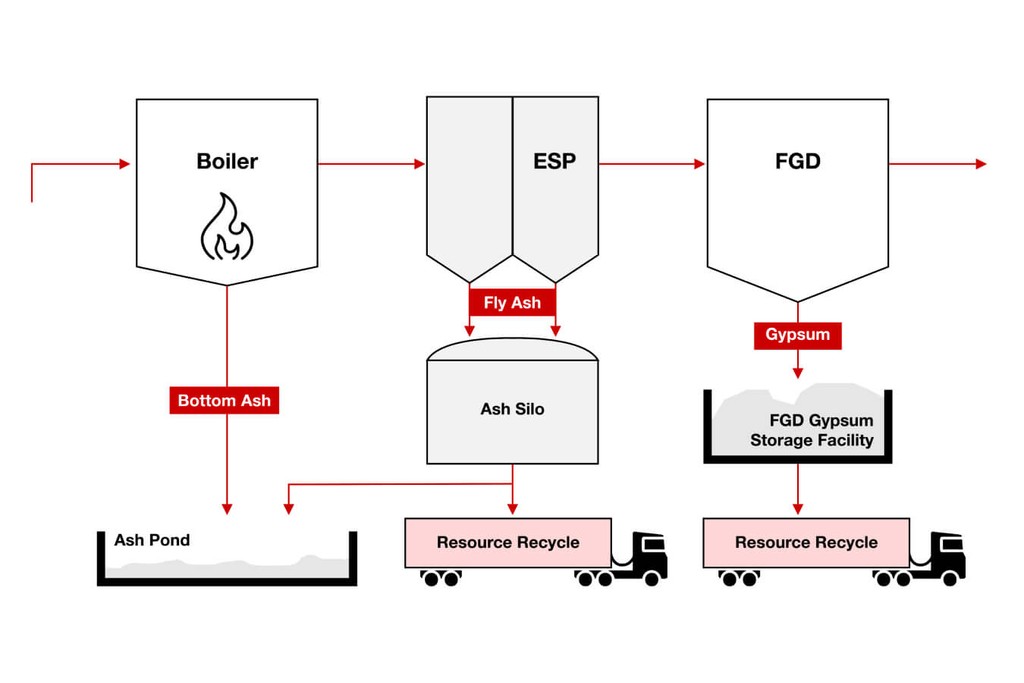

The production cycle of a coal burning power plant starts with coal being delivered to the furnace that drives the boilers. The boilers generate steam to drive turbines that generate electrical power.

Burning coal produces ash and flue exhaust gases as by-products. These are collected and separated into ash and gypsum, which are removed by conveyors to be taken for reuse and recycling.

What are the sustainable by-products of coal power production?

Modern coal power production generates two sustainable coal combustion by-products, fly ash and gypsum. Both are collected from flue gases, but by different processes. Flue Gas Desulfurization (FGD) is the process that recovers gypsum by using limestone and water to remove sulfur dioxide (SO2) from the furnace exhaust.

- Fly Ash removed by Electrostatic Precipitators

- Gypsum recovered by Flue Gas Desulfurization

An Electrostatic Precipitator (ESP) removes fly ash in a separate process from the furnace exhaust gases. FGD and ESP processing cleans the exhaust gases to reduce pollution and are sources of useful raw materials for other industries.

What are coal fly ash and gypsum used for?

Fly ash is commonly used as a strengthening agent in cement manufacturing, and gypsum is used for drywall cement panel manufacturing. Both gypsum and fly ash are used in agriculture as soil conditioners and stabilizers. Fly ash and gypsum from coal burning power stations are also used in road materials, construction and making artificial reefs.

How sustainable is FGD gypsum?

Research has found that FGD gypsum is a safe and sustainable product for agricultural use. The extraction process results in a high quality gypsum product with minimal contamination or impurities, and FGD gypsum can be cleaner than naturally occurring gypsum extracted from mines and quarries.

Cyclo speed reducers increase coal conveyors reliability

Transycko Cyclo drives and cyclo speed reducers are the best choice for coal conveyors and escalators because of their extreme reliability, compact high load carrying capacity, and predictable maintenance scheduling.

Conveyors and escalators transport the inward coal fuel feed to the coal power generators and remove by-products for reuse. Coal power plant conveyors and escalators need to transport heavy loads with reliable consistency as the power generation process is continuous. Any unexpected failures have serious consequences.

What are 3 advantages of cyclo speed reducers for power conveyors?

- Very high tolerance for momentary shock loading

- Long life, extended maintenance design

- Sealed for harsh operating environments

Transcyko cyclo speed reducers are designed for intermittent shock loadings of 500% of standard load ratings. This is considerably better than planetary gearboxes, which are commonly rated to withstand 300% momentary overloads.

The compact form factor of cyclo drives also makes it possible to upgrade conventional coal power plant conveyors to cyclo speed reducers without significant modifications to existing equipment and production lines, gaining the benefits of improved shock resistance and reliability without excessive costs.

Transcyko cyclo speed reducers for coal burning power plant conveyors

Transcyko is a leading global supplier of high quality cyclo drives and cycloidal speed reducers. Our range includes heavy and light duty cyclo gearboxes that are perfect for all types of power plant conveyor.

We offer full servicing, parts and cost effective drop-in replacements for Sumitomo

cyclo designs, allowing an easy transition from Sumitomo to Transcyko products if you are looking at improving your power plant efficiency and building cost over lifetime savings.

As well as our rugged range of cyclo products, we manufacture helical bevel gearboxes and planetary gearboxes. We combine extensive experience and advanced technology to supply custom configurations for any power plant drive, gearbox or speed reducer requirements.

Contact us to discover cyclo gearboxes and cyclo speed reducers manufactured to the highest quality standards, and experience the support and informed expertise of our excellent technical and maintenance teams.