Transcyko Cyclo Drives With Flanges For Servo Motors

Applications of Cyclo Drives for Servo Motors

Standard cyclo applications use fixed speed motors for a constant output speed. When a cyclo drive is matched to a servo motor for variable speed output we discover a range of possibilities that cannot be achieved with conventional drives.

- Variable Speed

- High Power

- Start / Stop Operation

- Compact

- Reliable

- Convenient

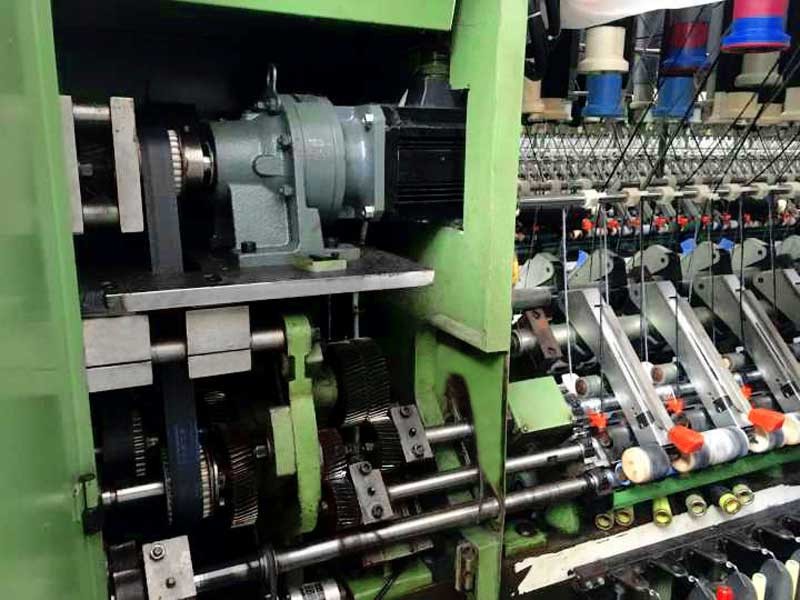

Cyclo drives driven by servo motors are used in a range of industries where high power output, reliable, consistent service and variable speed in a small compact unit offer competitive advantages. Cyclo drives with flanges for servo motors are already the standard for aluminium and mylar foil lamination, textile manufacture, and variable weight product conveyors.

Cyclo servo motors are very precise, reliable and compact for their power rating with low backlash. They can also be started and stopped very rapidly due to their high torque tolerance. These features make them suitable for a wide range of applications that require mechanical strength with servo flexibility. Synchronised operation of multiple and parallel conveyors and product lines is easily achieved with cyclo servo combinations

- Production Line Conveyors

- Automation

- Robotics

- Food Processing

- Machine Tools

- Automotive Manufacture

- Parcel Handling

- Textile Manufacture

- Laminating Machines

Cyclo drives with flanges for servo motors enable stop start conveyor systems to carry a wide range of items of different weights at different speeds without modifying the output ratio. The same cyclo drive and servo motor combination can be switched between carrying different products or categories of item simply by changing the output rpm of the servo motor. This makes cyclo drives with servo motors ideal for delicate and precise light to medium load handling of electronics and food products.

Cyclo drives with flanges for servo motors are rapidly overtaking single speed motor combinations as the logical choice because of their higher performance, versatility and lower operational costs. Traditional combinations of servo motors with helical gear drives suffer from poor reliability and durability, high costs, size and weight. This makes cyclo drives a better choice in the competitive marketplace.

Benefits of Transcyko Cyclo Drives for Servo Motors

Robust and very reliable cycloid gearing, cross-brand compatibility, high reduction ratios, torque capability, and high power output make Transcyko cyclo drives for servo motors the best choice. Cyclo drives feature smooth rolling contact between gears that shares the load evenly between components and almost eliminates the possibility of tooth breakage. This makes cyclo servo motors smaller and more reliable than traditional helical gear systems of the same power rating.

Our cyclo drives have a motor capacity between 0.4kW and 18.5kW, twice the capacity of cyclo drives available from other leading manufacturers. This is combined with high torque capability that allows for large reduction ratios, which is why Transcyko cyclo drives are the obvious solution for the most demanding servo motor applications.

- High Torque Capability

- High Speed Reduction Ratios

- Very High Motor Capacity

Cyclo drives are very durable and have reduced maintenance requirements compared to other types of drives. The even wear pattern of cyclo drives enables routine servicing to be scheduled to times that ensure minimal loss of production without fear of potential sudden failure.

- Durable by Design

- Reliable in Operation

- Low Maintenance

Direct Replacement For Other Manufacturer Servo Cyclo Solutions

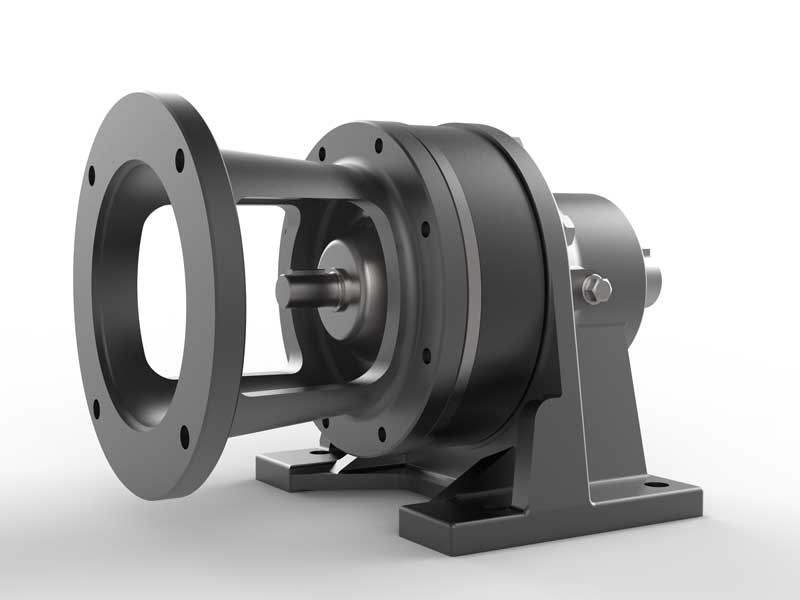

Transcyko cyclo servo motors are designed with customer convenience in mind and to be compatible with the widest range of existing equipment configurations. Our products can be used as direct, cost-effective replacements for drives supplied by other leading manufacturers including Sumitomo. Transcyko flange mount cyclo servo motors can be fitted to keyed or unkeyed shafts in any mounting direction, and service components as well as complete units are swappable for other brands without modification.

- Flange Mount

- Keyed or Keyless Shafts

- Cross-Brand Compatibility

If adapters are required for output shaft connection we have ensured our designs are easy to assemble so you can fit them yourself or our responsive and expert service support team can do this for you.

Excellence in Service & Support

Our customers discover significant competitive advantages come from partnering with Transcyko products. Support. installation and maintenance are easy no matter what your requirement. Our flexibility in design, options and installation is matched with cross-brand compatibility for parts, servicing and replacement. We are focused on assisting our customers to achieve the best possible result in the easiest and most cost-effective way.

Our customers enjoy direct access to the highly skilled maintenance and customer support services we have built over many years of experience as a leading cyclo servo motor manufacturer. Our in-house vertically integrated design and production ensures we respond very rapidly to customer questions and have the expertise on-hand to quickly provide solutions to your needs.

Technical Info

Standard-Backlash Series

| Peak Torque Allowable | 12,125 lb-in (29.7-1370 Nm) |

| Motor Capacity | 0.4 kW to 18.5 kW |

| Output Shaft Direction | Any: Horizontal or Vertical |

| Mounting Style | Foot Mount, Case Mount, Flange Mount |

| Frame Size | 12 Sizes (from 608 to 619) |

| Reduction Ratio | 6:1 to 87:1 |

Low-Backlash Series

These are a customized product that Transcyko build to meet your specific requirements. We make low backlash series to max 6 arc min and (12 arc min for reduction ratio 6). Please contact our expert team, who are always happy to discuss how we can best help you achieve the most efficient and effective solution to your needs.

The Logical Choice: Transcyko Cyclo Drives For Servo Motors

We offer our customers a one-stop shop for your cyclo drive servo motor requirements, no matter how large or how small. Our in-house design and service teams provide rapid and effective solutions that are focused on your specific business requirements.

In business-critical operations, cyclo drives offer the most reliable and durable option. Service intervals can be planned to meet the demands of the business cycle without the risk of unexpected failures and expensive stoppages. Cross compatibility of Transcyko components and drives with products supplied by other manufacturers maintains the smooth throughput of your business work flow.

We are always happy to offer technical advice and assistance at all stages of your business process to ensure you get the best possible drive for your requirements at a cost-effective price. Our customers have discovered that Transcyko cyclo drives for servo motors are the logical choice and we are the ideal partner to help them achieve and maintain business success. If you would like to find out more about Transcyko cyclo drives for servo motors or other product lines please contact us.