The Transycko All-in-One Gearbox Solution for Coal Conveyors

An all-in-one solution for coal conveyor gearbox installations gives our industrial customers a simple, cost-effective alternative to Sumitomo Paramax 9000 Series gearboxes with the assurance that all components and ancillary services have been selected and integrated to provide a high performance, efficient solution that matches their coal conveyor needs.

What is included in the Transcyko coal conveyor gearbox solution?

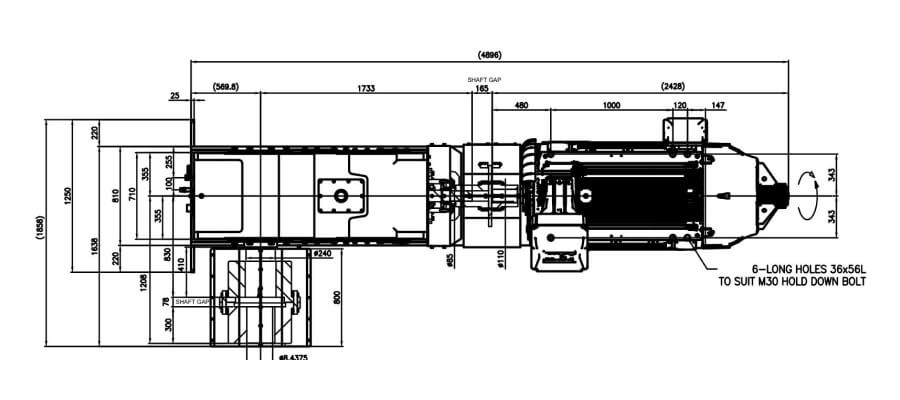

The Transcyko TSG helical gearbox is the core component of our coal conveyor solution. The integrated package consists of the Transcyko gearbox, WEG motor, brake, brake disc, coupling and base frame. All components are matched to ensure reliable, consistent performance for efficiency and reduced maintenance overheads.

- Transcyko TSG gearbox

- WEG motor

- Brake

- Brake disc

- Coupling

- Base frame

The Transcyko TSG gearbox that drives our coal conveyor package is the product of our precision gearbox engineering and subjected to our stringent, certified, quality control standards to ensure flawless performance that will not let you down. It is designed to be easily swapped with equivalent Sumitomo Paramax speed reducers to upgrade existing Sumitomo equipped lines.

Transycko speed reducers are used in the coal industry and coal power plants for a range of conveyor tasks, this is because Transcyko speed reducers give you extremely high reliability with reduced maintenance overheads and excellent customer service through all stages of design, manufacturing, supply and commissioning.

Many existing coal conveyors use Sumitomo Paramax or similar gearbox and motor systems, and this leads to a tendency to return to Sumitomo for repairs and replacements, which can be an expensive and time consuming experience. Transcyko designs and engineers gearboxes and speed reducers that are intended for maximum compatibility and interoperability with other gearbox brands, including drop-in replacements for Sumitomo, Zambello, Bonfiglioli and SEW Eurodrive gearboxes.

A significant advantage of working with Transcyko for your gearbox and speed reducer requirements is our willingness and ability to provide you with repair, maintenance and replacement solutions across all major gearbox and speed reducer applications provided by the leading industry manufacturers, all with the responsive high customer service and support levels that have been at the core of our global partnerships for more than forty years.

What are the advantages of Transcyko vertically integrated gearbox manufacturing for coal conveyors?

Transcyko has a long history of gearbox and speed reducer manufacturing to the highest quality control standards, and our vertically integrated business model gives us complete control and oversight over every single product and project no matter how big or how small. The same engineering, development, production, testing and logistics teams are in charge of every aspect of the specification, manufacturing and supply of your next coal conveyor gearbox system.

Our integrated approach to high quality solutions for our coal industry partners gives us an enviable reputation for both reliable quality and excellent customer service with responsive after sales support and maintenance. When you contact us with any questions or queries about your project before, during or after commissioning you can talk to the people who have been responsible for every stage of the process. This also results in extremely rapid turnaround times for new and continuing projects.

Transcyko skills & capabilities for customized ODM gearbox manufacturing

Transcyko has been serving our global customers with reliable speed reducer and gearboxes for many decades. We have the advantage over our competitors of maintainining highly experienced, vertically integrated, R&D, engineering, production and testing teams at our main facility in Taiwan. This gives us the ability to not only provide a rapid turnaround for our portfolio of standard designs, but also to design, prototype and supply customized ODM solutions.

We manufacture gearboxes, gearbox assemblies, speed reducers and components of all sizes, from coal power conveyors and industrial centrifuges to precision semiconductor manufacturing conveyors. Contact us to discover how our long expertise and comprehensive in-depth knowledge can be put to work to give you complete solutions for your coal conveyor needs.