Bucket Elevator Drives Replacement & Repair

What Are Bucket Elevator Drives?

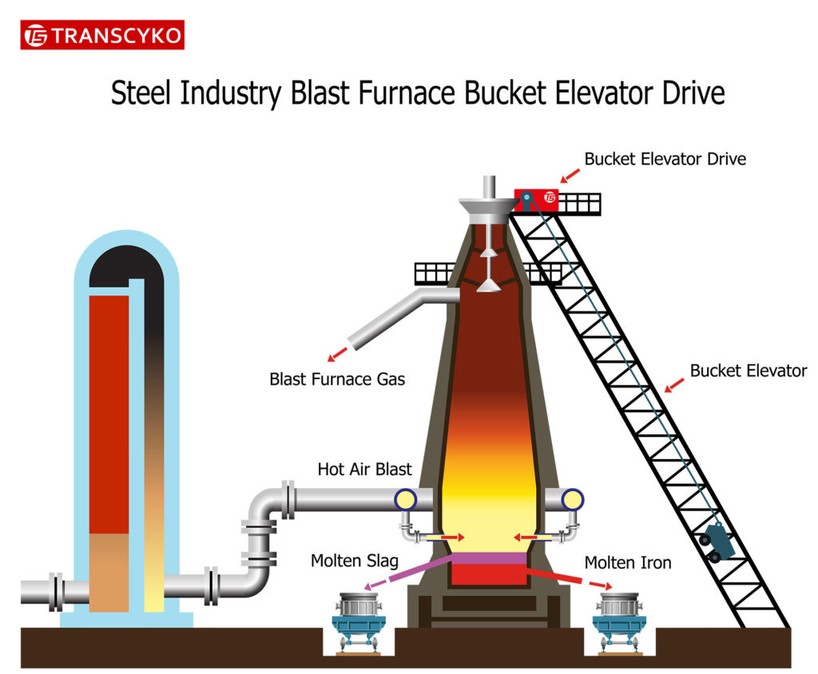

Bucket Elevator Drives are designed for the vertical transport of large quantities of materials. The bucket containers are attached to a continuous conveyor belt which passes around a drum at the base of the elevator. The buckets collect their load at the base of the system, are carried up to the top and then release their material as they are rotated at the top of the drive system.

These drive systems are often required to carry enormous loads through vertical elevations of 100-200m or more and they must transport these loads without creating large quantities of dust in the process.

Bucket elevator systems are used widely in Heavy industry manufacturing plants such as steel production to efficiently transport bulk material vertically through the production process. Bucket elevator bevel helical gear units are one of the most widely used applications for our Transcyko TSG gearbox range. These high efficiency drive units are in use now across a range of industries that rely on them for material transport:

- Iron & Steel Industry

- Food Industry

- Cement & Aggregate Industry

- Fertilizer Industry

- Chemical Industry

- Mining Industry

The gearboxes for bucket elevator systems must be soft starting because of the high starting power, this is achieved by fluid couplings in the drive chain. Our Transcyko TSG bevel helical gear units are the most common choice for this application.

Is Gearbox Replacement The Best Solution?

Legacy industrial gearboxes and equipment may appear at first to be cheaper to repair, but as these systems become older and repair costs increase, replacement with newer technology which is more durable and requires less maintenance is often cheaper in the long run. Replacement also provides additional efficiency and reliability benefits for production.

Cost Effective Bucket Elevator Drive Replacement Solutions

Changes to any major production components can be very costly for operations. Minimizing disruption, managing costs and ensuring ongoing maintenance are vital for efficient upgrades and retrofitting to deliver real value to the business. Transcyko large industrial gearboxes can be retrofitted to suit your existing space and location configurations.

“Replace The Old Repair The New”

Other factors such as parts availability, technical service quality, and flexibility may make a move away from an older traditional brand to a more responsive bucket elevator drive partner a more effective solution for your business.

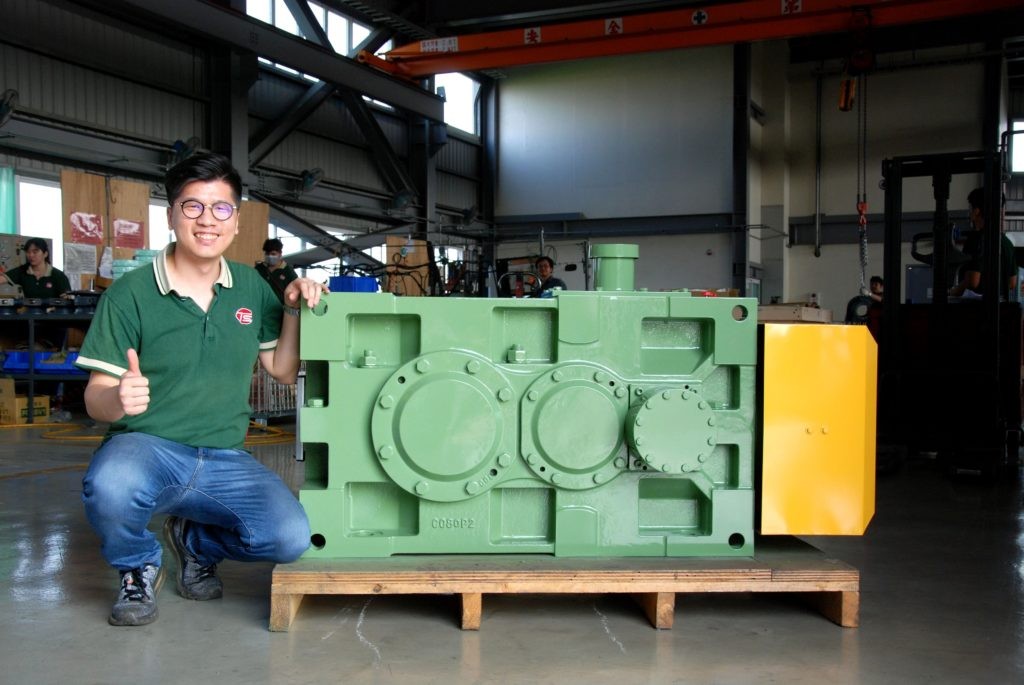

Transcyko “Drop in” bucket elevator gearbox solutions allow for rapid replacement and upgrade to newer, more efficient technologies with minimal disruption to production operations. Our bucket elevator drive solutions will replace your legacy Sumitomo or other brand gearboxes with newer, easier to maintain designs, backed up by Transcyko’s renowned gearbox durability, advanced designs, and excellent service.

Better Bucket Elevator Drive Solutions By Design

Transcyko Heavy Duty Industrial drive units carry out the most difficult tasks with maximum reliability. We utilize a modified crowning design to decrease noise, decrease vibration and counter the effects of offset loads. Our gearboxes also feature spherical roller bearings which achieve low friction coefficients with a heavy load bearing capacity.

All of our TSG series gearboxes deliver unmatched reliability in heavy industry operations, with high torque and load bearing capacity as well as low noise and increased thermal performance capabilities.

Transcyko Bucket Gear Drive Inspection:

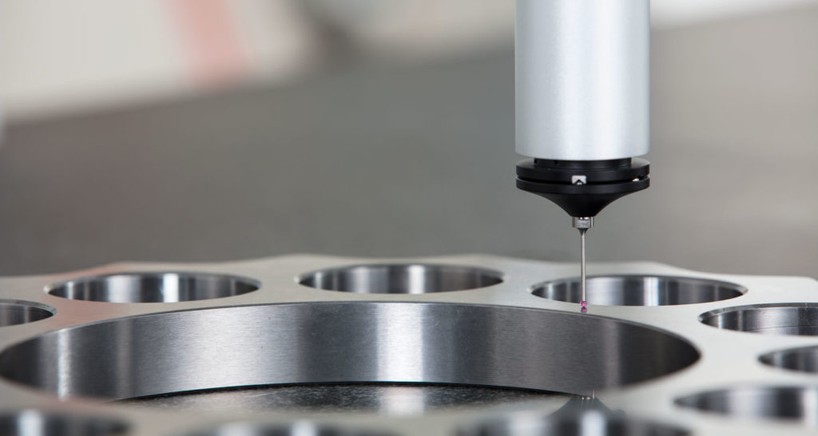

All of our heavy-duty gearboxes are rigorously inspected to mee the most demanding of customer applications. Our bucket elevator drives deliver maximum performance and reliability as we understand they are a vital component in your production drive train:

- Gear Grinding to DIN4

- Metallographic analysis

- Magnetic Particle Testing

- Tooth Contact Analysis

To find out more about our customized solutions for material transport in heavy industry, please contact us.